6

Hardware

Perform

12

System

Good craft

7

Selection

High quality

18

Industry

Experience

Precision metal stamping manufacturing 18 years

+86-752-3520737

+86-15019291973

About US

Recommended

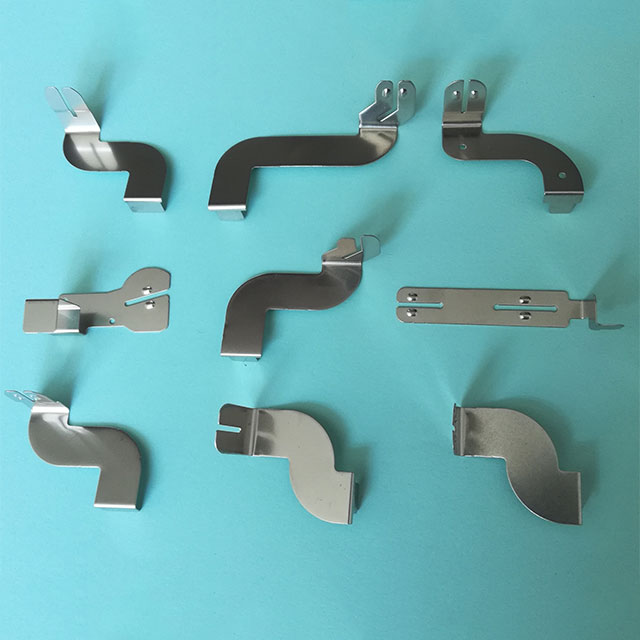

5G communication hardware 1

5G communication hardware 2

5G communication hardware 3

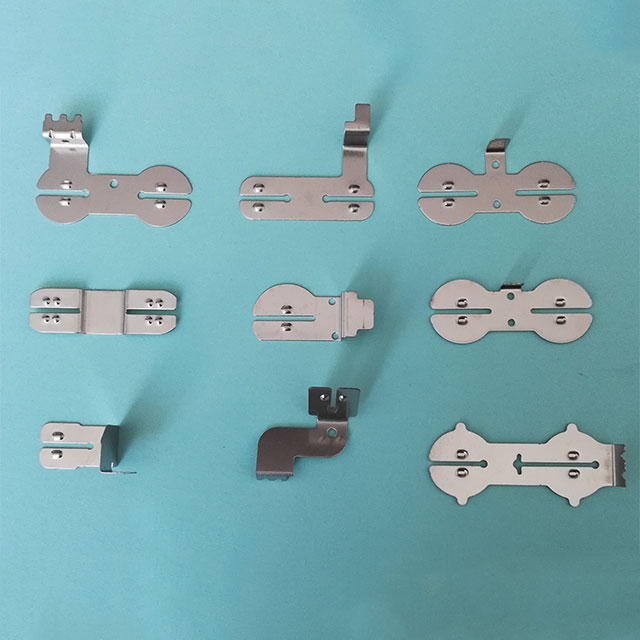

Nickel connection piece 14

Nickel connection piece 13

Nickel connection piece 12

Nickel connection piece 11

Nickel connection piece 10

Nickel connection piece 9

Nickel connection piece 8

5G communication hardware 4

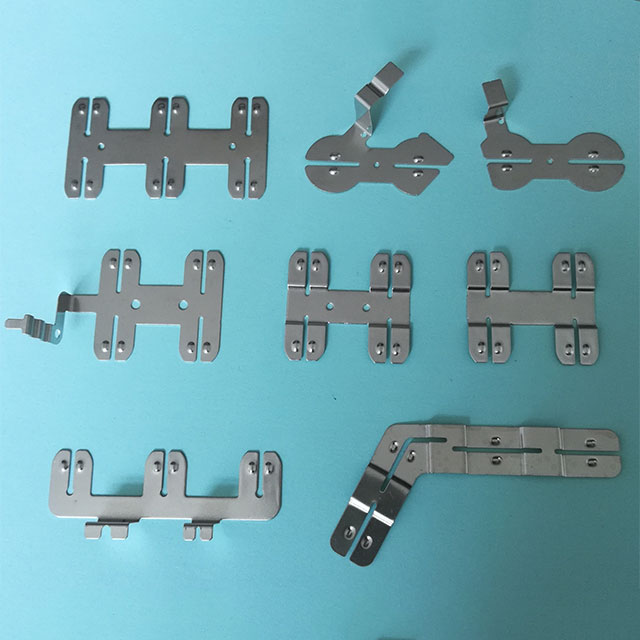

Power battery nickel sheet 7

Nickel connection piece 7

5G communication hardware 5

Power battery nickel sheet 6

Contact us

TEL+86-752-3520737-610

Phone+86-15019291973

E-mailjinggongjing@aliyun.com

AddressNankeng Village, Xinxu Town, Huiyang District, Huizhou City, Guangdong Province, China

Company Profile HOME >> About US >> Company Profile

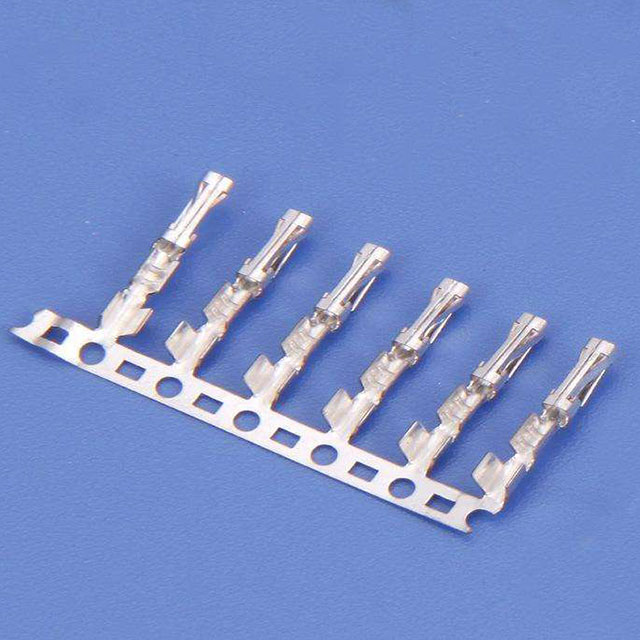

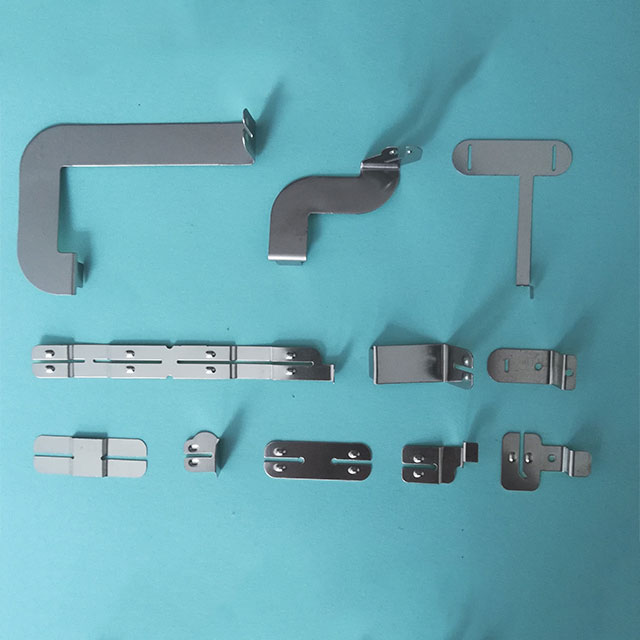

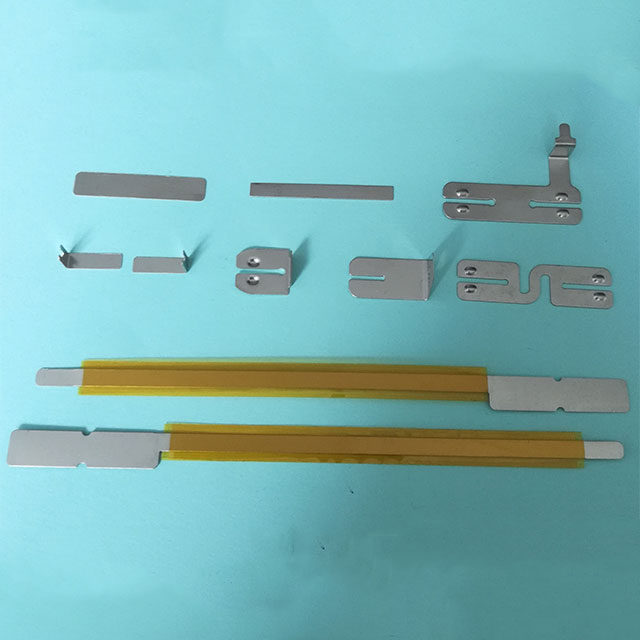

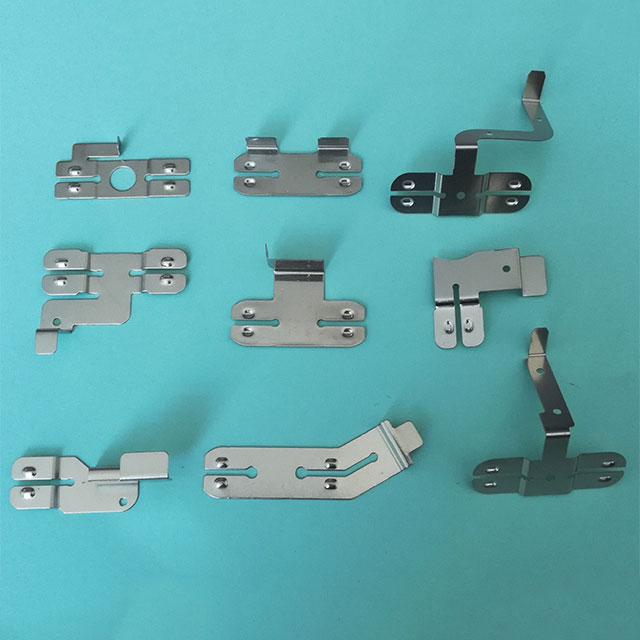

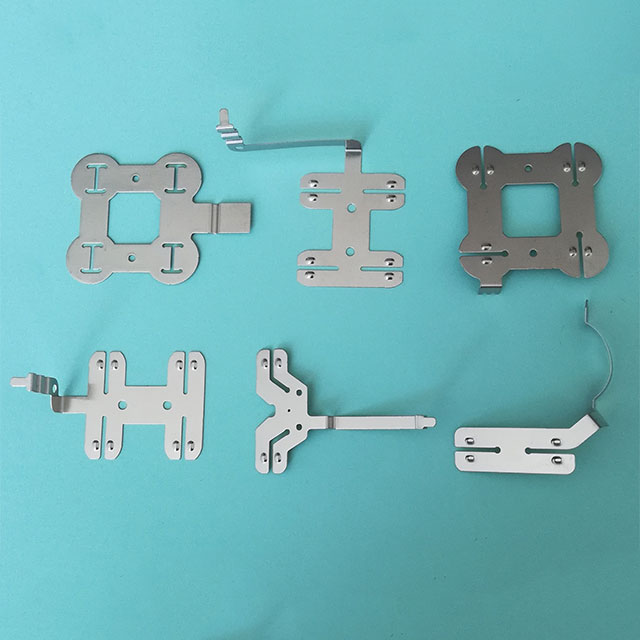

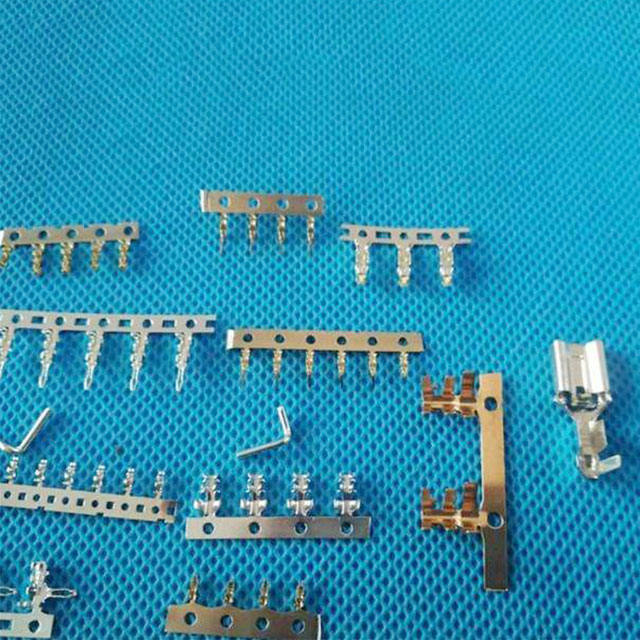

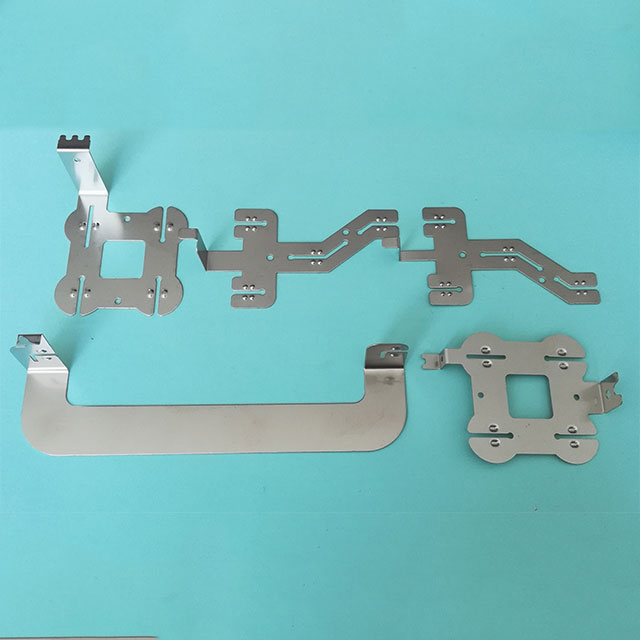

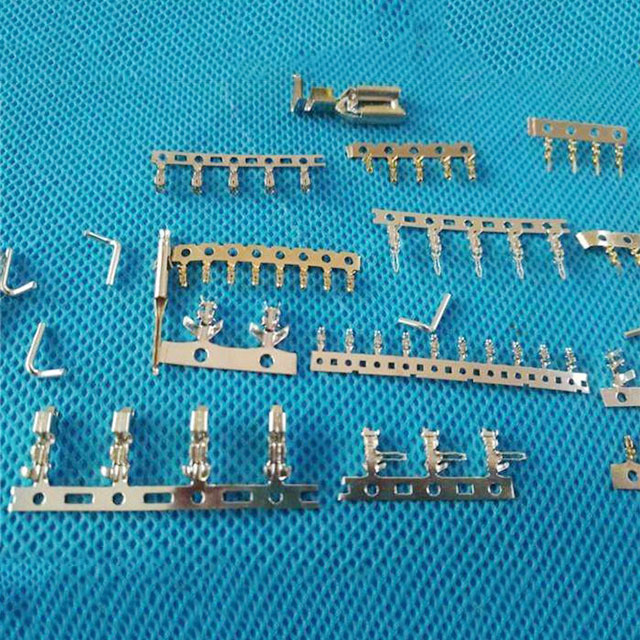

Huizhou Jinggong Precision Metal Products Co., Ltd. was established on September 26, 2002. It is a precision metal stamping, processing and production enterprise, mainly engaged in development and design: battery link nickel sheets, battery pack charging female inserts, battery pack charging terminals, heat dissipation hardware, contact shrapnel, power supply positive and negative shrapnel, battery pack connecting pieces , Contact hardware, etc. The company has a plant area of 10,000 square meters, strong technical force, complete equipment, and actively absorbs domestic and foreign experience. It has from parts design, product design, hardware stamping continuous mold development, and accessory production, focusing on meeting customer needs and cooperating with customer research and development professional technology team. Among them, there are 25 professional design backbones and technicians, and 80 production operators. We have brand-new advanced precision production equipment and quality inspection equipment, complete product production realization process, and complete equipment.

development path:

September 2002: Established Jinggong Precision Mold Factory. Professional development. Design and manufacture precision molds.

September 2006: Shenzhen Jinggong Precision Metal Products Co., Ltd. was established. Professional development, product design, manufacturing and production of stamping hardware, fully completed the development, design, stamping and production of the entire production chain, the battery industry customers include: Desai battery, Fujian Scud, Yiwei Lithium Energy, etc.

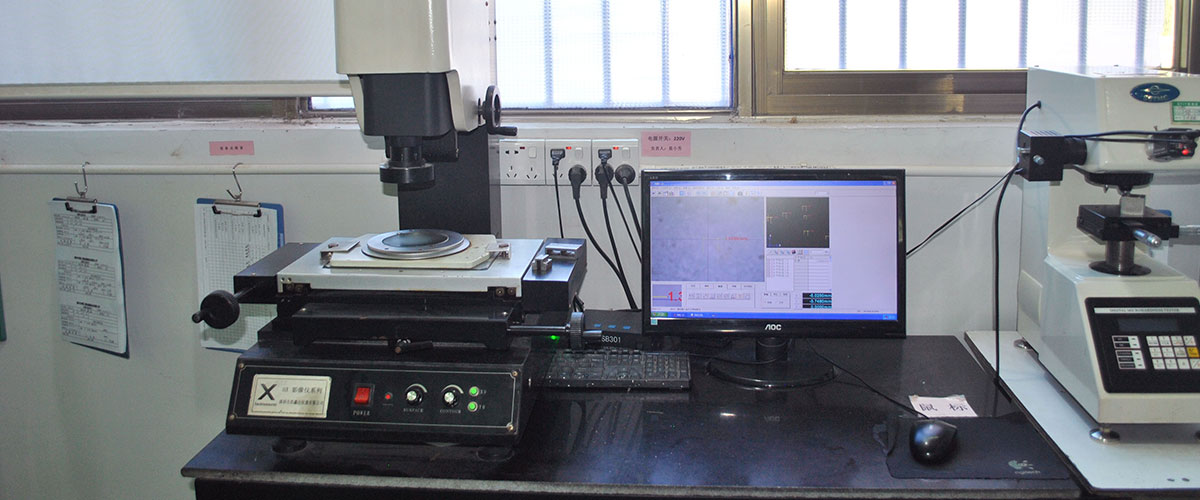

October 2007: The company fully completed and implemented ISO9001, ISO/TS16949 international quality management system and environmental protection management system.

June 2008: The company began to contact the new energy lithium battery industry, specializing in the research and development of new energy lithium power batteries and energy storage lithium battery accessories. After ten years of hard research results, the company’s development team has certain research and development experience in new energy lithium battery products. Production technology can help customers complete product design and production in a set of manufacturers. The company is committed to providing customers with solutions in the field of new energy lithium battery power supplies, allowing customers to use higher quality lithium battery accessories. Now the company has established a stable cooperative relationship with well-known domestic enterprises, and the company continues to innovate and follow the steps of new energy companies.

September 2018: The company moved from Shenzhen to Huizhou, and the company name was changed to: Huizhou Jinggong Precision Metal Products Co., Ltd., starting a new journey.

company culture:

The company adheres to the business philosophy of "extensive design, precision manufacturing, fine service, and excellence", cherish every opportunity in the development, and establish a good cooperative relationship with customers. Survive by quality, develop by reputation, operate with integrity, and regard reputation as our life. For a long time, our principle of continuous innovation, development and common development has taken customer satisfaction as the company's forward driving force, so that customer requirements can be met to the greatest extent.

24 processes behind the grinding, is a quality and rest assured.

Perform

Good craft

High quality

Experience

Faster/more efficient/quality/on-time delivery

With more than 100 people mold production team, professional production team, Well-designed, precision manufacturing, fine service, excellence, Years of customized experience, first-class product technology, quality assurance, efficient and efficient production.

Raw materials are imported from Japan, Germany and Sweden, with stable performance and a service life of more than 5 years; Have professional heat treatment supporting services, to provide you with accurate and true heat treatment reports, strict quality inspection system and testing equipment, high precision, tolerance of up to -002um, the first in the industry.

Material sampling rationalization, save raw material costs, open the number of holes, stamping production efficiency is high, stamping processing costs savings, mold design costs are free, stamping life up to 300 million times, mold stall cost savings.

| Precise metal High cost performance service |

Eighteen years of ingenuity together, casting metal stamping products