6

Hardware

Perform

12

System

Good craft

7

Selection

High quality

18

Industry

Experience

Precision metal stamping manufacturing 18 years

+86-752-3520737

+86-15019291973

Recommended

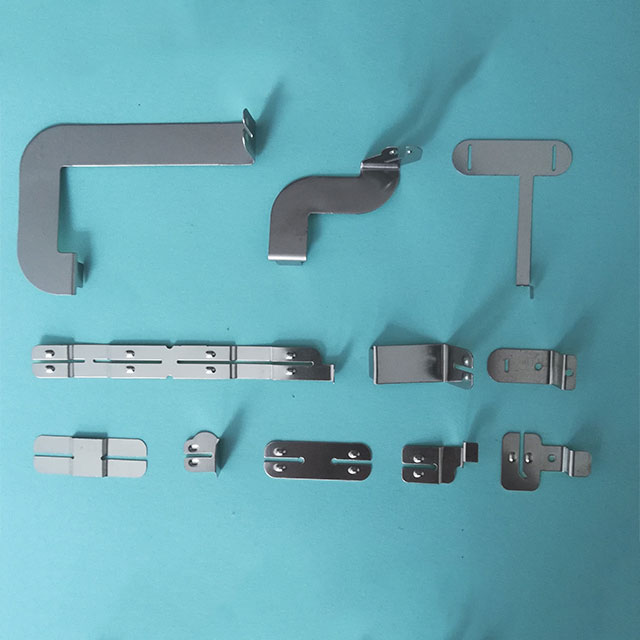

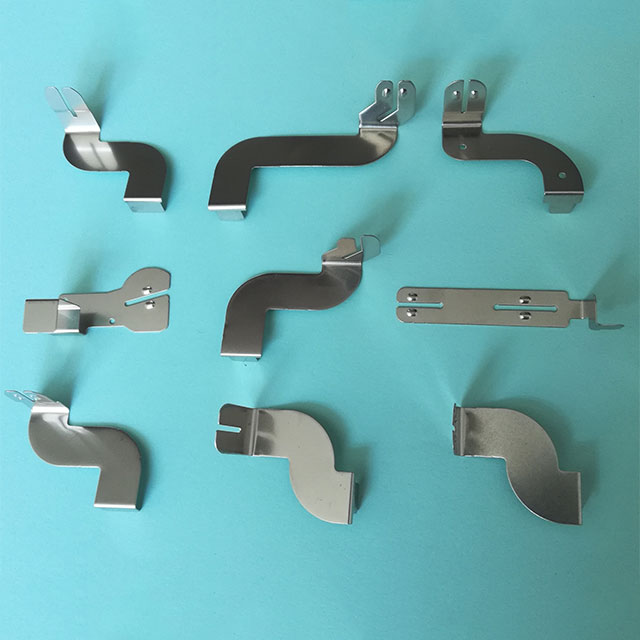

5G communication hardware 1

5G communication hardware 2

5G communication hardware 3

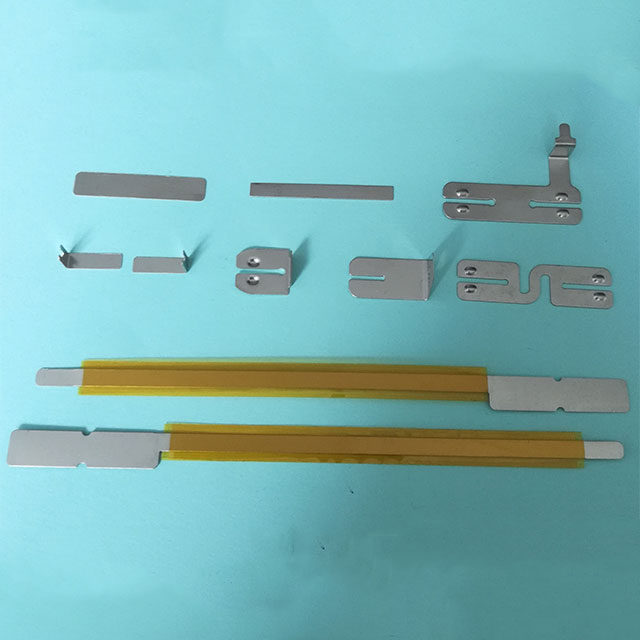

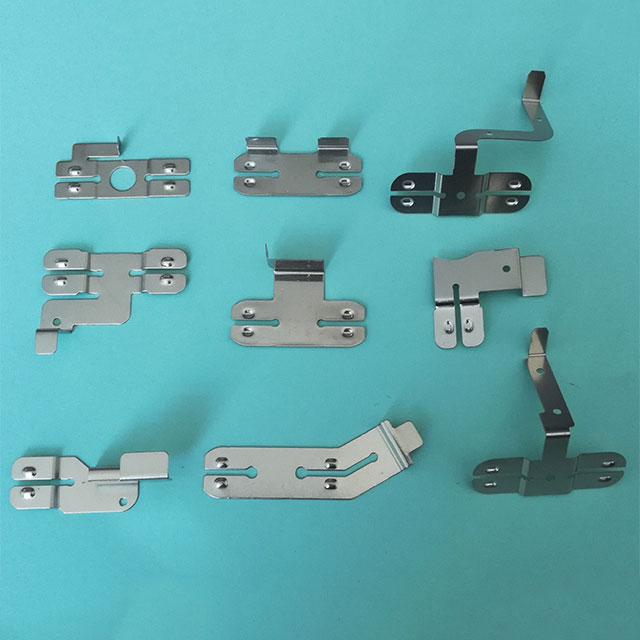

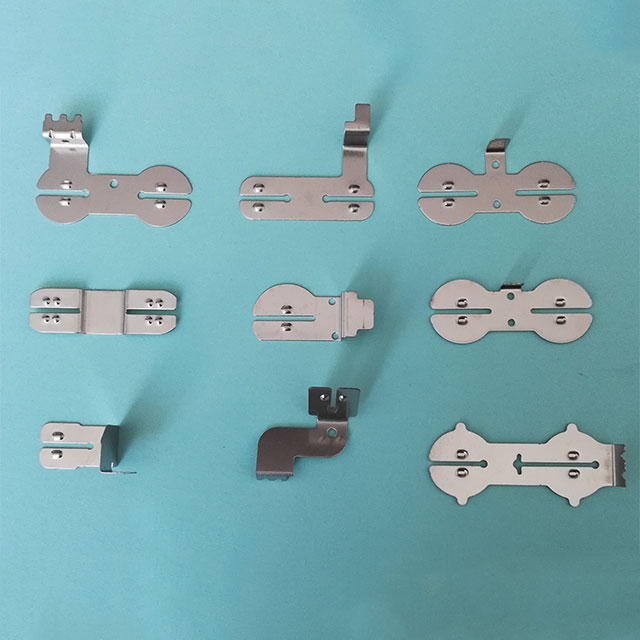

Nickel connection piece 14

Nickel connection piece 13

Nickel connection piece 12

Nickel connection piece 11

Nickel connection piece 10

Nickel connection piece 9

Nickel connection piece 8

5G communication hardware 4

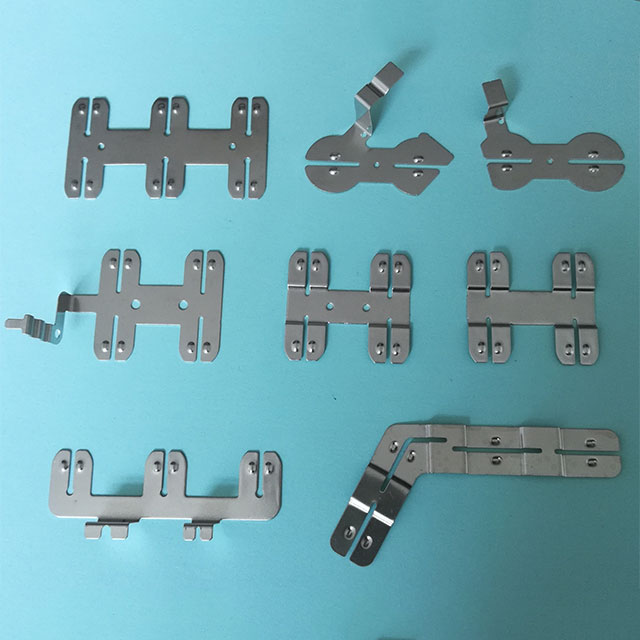

Power battery nickel sheet 7

Nickel connection piece 7

5G communication hardware 5

Power battery nickel sheet 6

Contact us

TEL+86-752-3520737-610

Phone+86-15019291973

E-mailjinggongjing@aliyun.com

AddressNankeng Village, Xinxu Town, Huiyang District, Huizhou City, Guangdong Province, China

Company News HOME >> News >> Company News

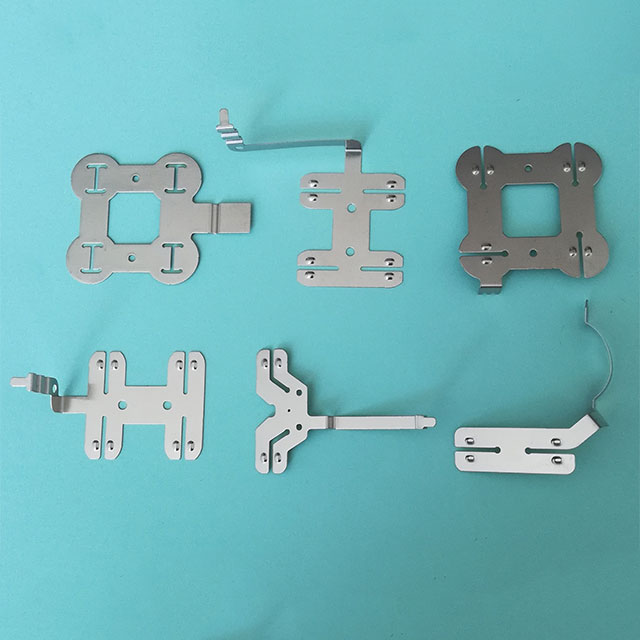

With the development of China’s economy, more and more things need to be charged, which in turn drives the mass production of power pins for metal stamping parts, and the requirements for them are also getting higher and higher.

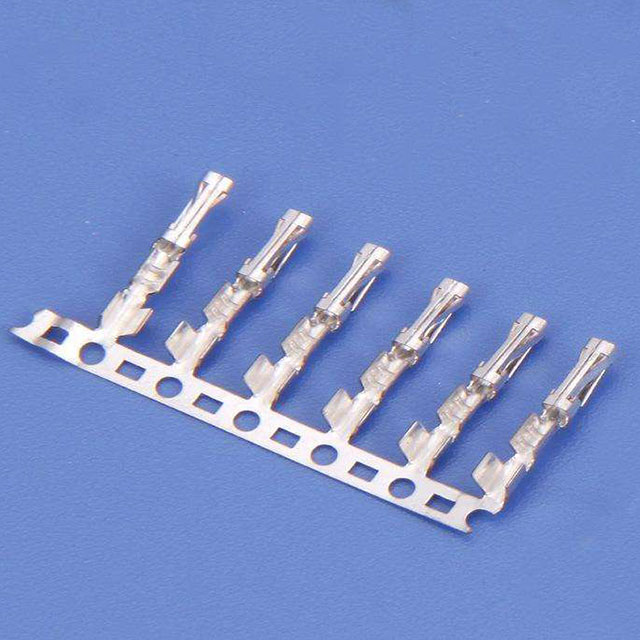

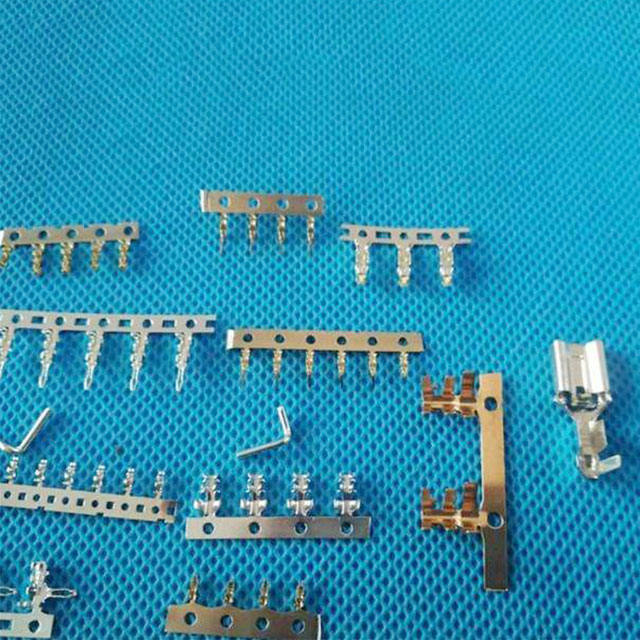

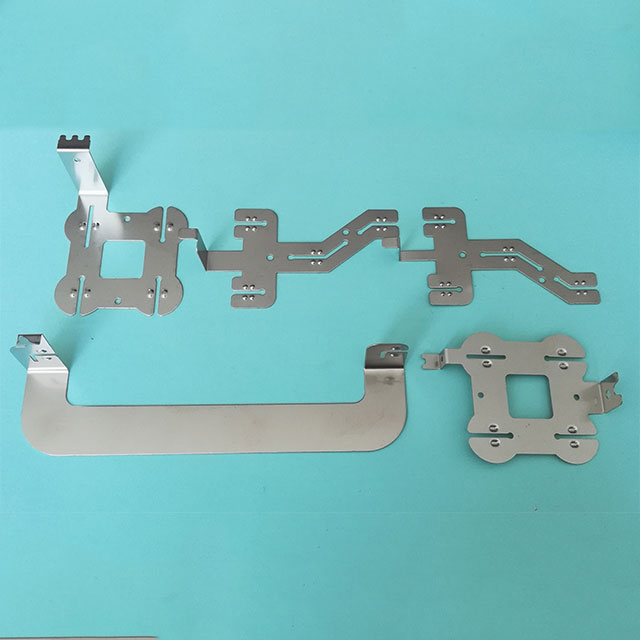

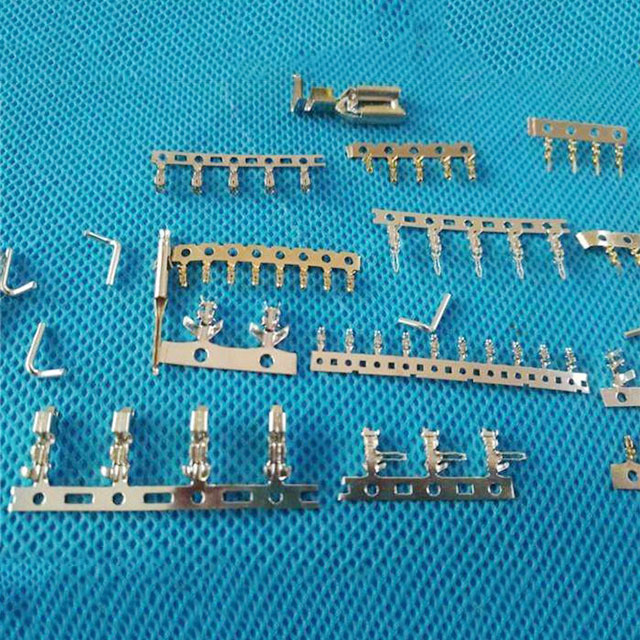

Because the power pins in the past are easy to be broken and unstable, it is prone to danger; the design of the power pins is not up to standard. The current design generally opens a small hole at the top to facilitate fixing when the plug is installed and not easy to break. (As shown in the picture) The power pin is also called plug inner mold, plug inner frame, and plug accessories. Divided into: Chinese standard pin, British standard pin, American standard pin, European standard pin, etc.

The structure is mostly UL films. Painted with environmentally friendly copper. The size is mostly around 1.6*6.3*28mm (for reference only), and the specific size needs to be combined with actual needs. Scope of application: car fuse box, fuse holder; used for control circuit board (protect important components), power plug, etc. Plating: matte tin/bright tin/nickel

Previous page:Nickel battery connector

Next page:New energy power battery...

What is the best hardware shrapnel, heat sink, and shielding cover? Huizhou Seiko is the...

2020-08-15

The role of contact shrapnel and production process

2020-08-15

Nickel battery connector

2020-08-15

Power pin for metal stamping parts

2020-08-15

New energy power battery accessories requirements

2020-08-15

24 processes behind the grinding, is a quality and rest assured.

Perform

Good craft

High quality

Experience

Faster/more efficient/quality/on-time delivery

With more than 100 people mold production team, professional production team, Well-designed, precision manufacturing, fine service, excellence, Years of customized experience, first-class product technology, quality assurance, efficient and efficient production.

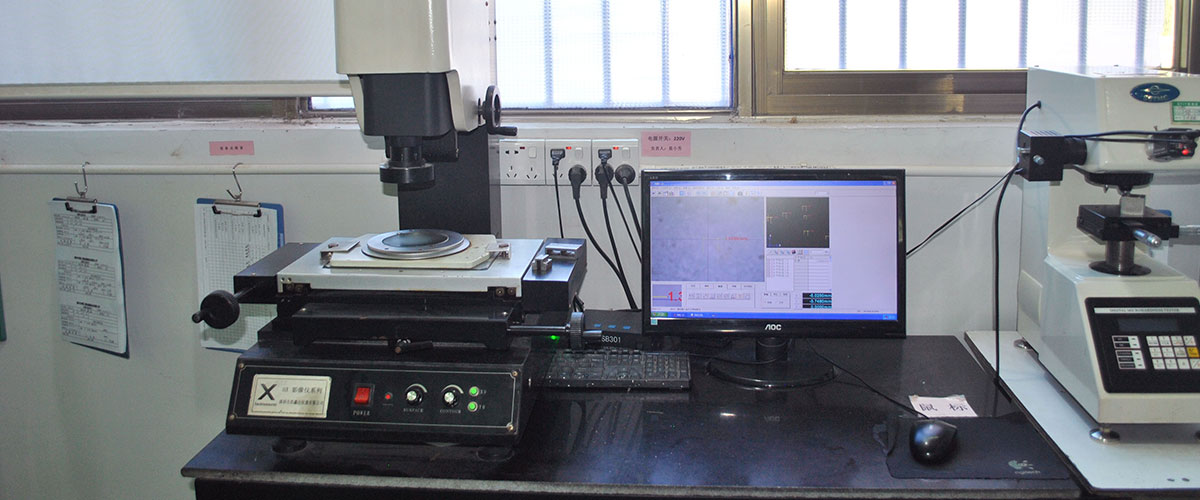

Raw materials are imported from Japan, Germany and Sweden, with stable performance and a service life of more than 5 years; Have professional heat treatment supporting services, to provide you with accurate and true heat treatment reports, strict quality inspection system and testing equipment, high precision, tolerance of up to -002um, the first in the industry.

Material sampling rationalization, save raw material costs, open the number of holes, stamping production efficiency is high, stamping processing costs savings, mold design costs are free, stamping life up to 300 million times, mold stall cost savings.

| Precise metal High cost performance service |

Eighteen years of ingenuity together, casting metal stamping products