6

Hardware

Perform

12

System

Good craft

7

Selection

High quality

18

Industry

Experience

Precision metal stamping manufacturing 18 years

+86-752-3520737

+86-15019291973

Recommended

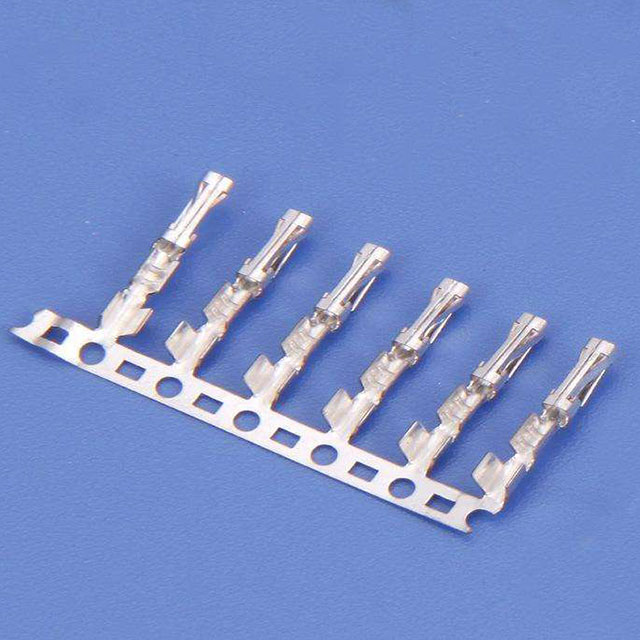

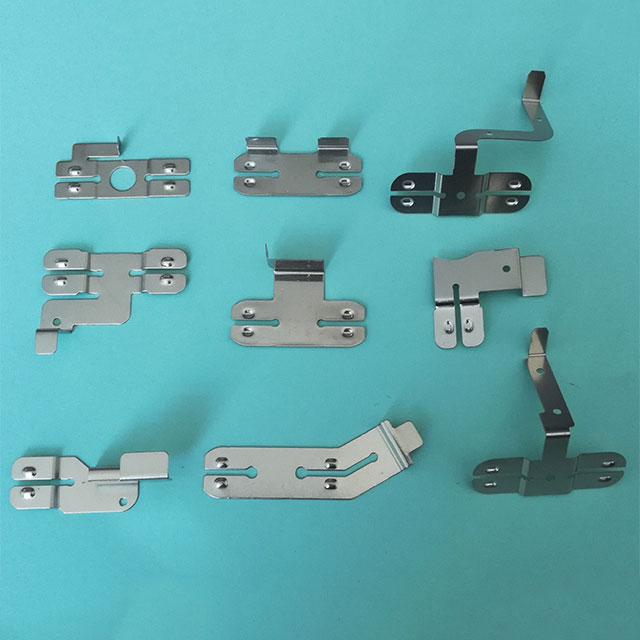

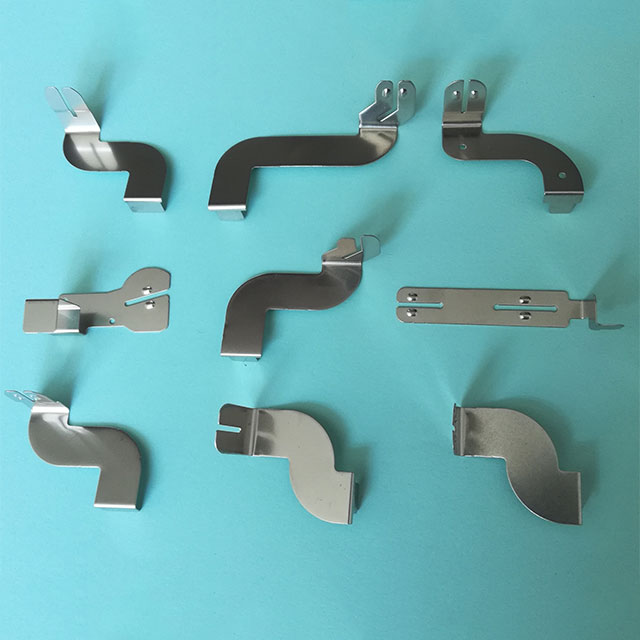

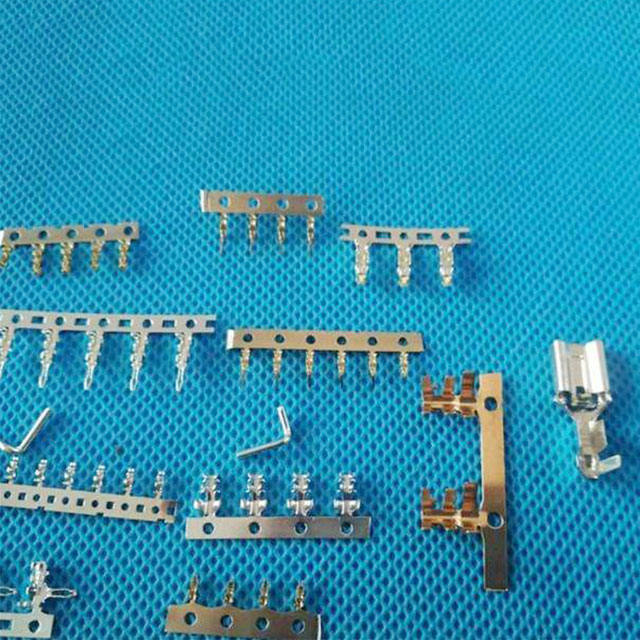

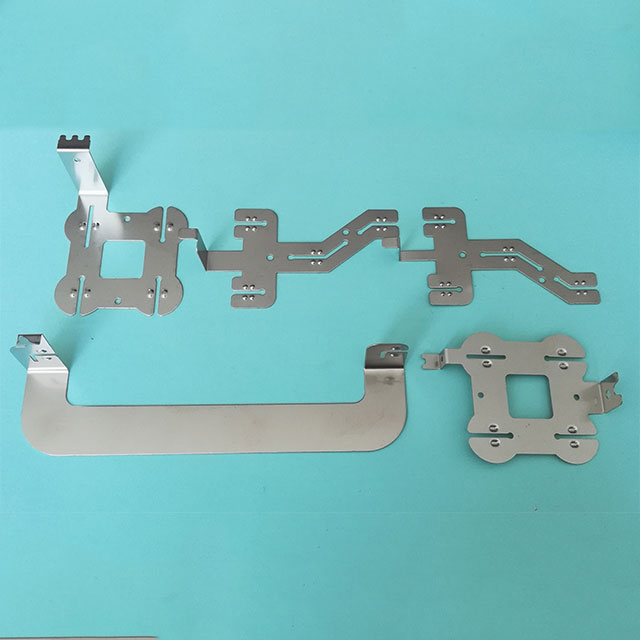

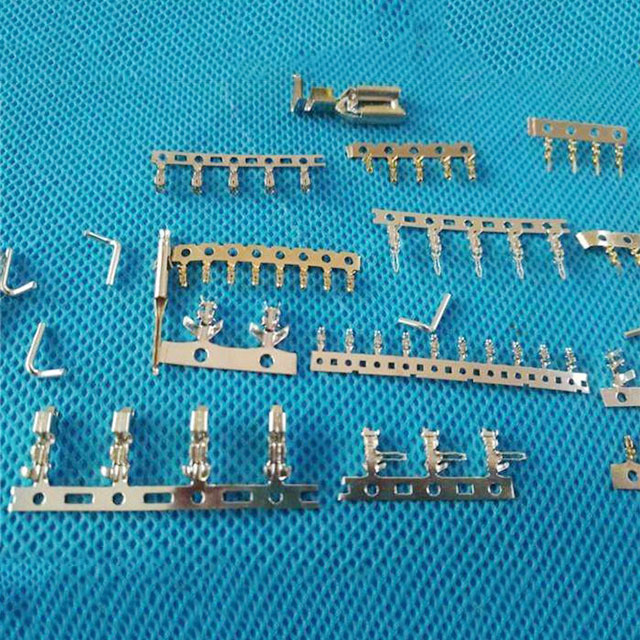

5G communication hardware 1

5G communication hardware 2

5G communication hardware 3

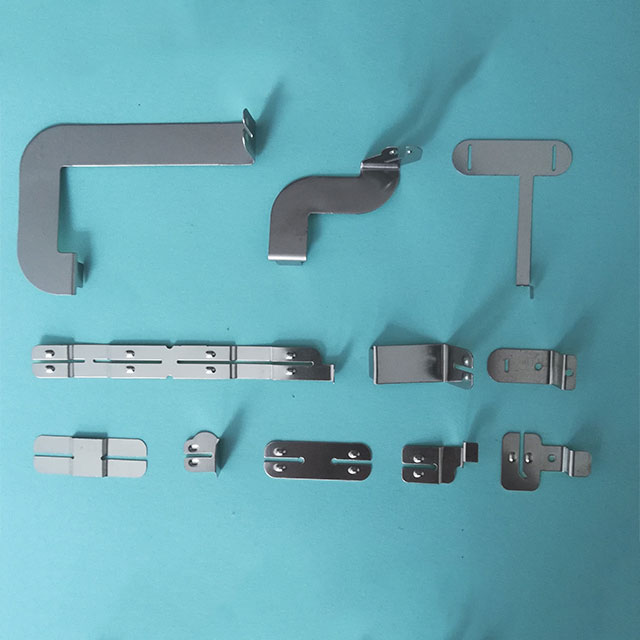

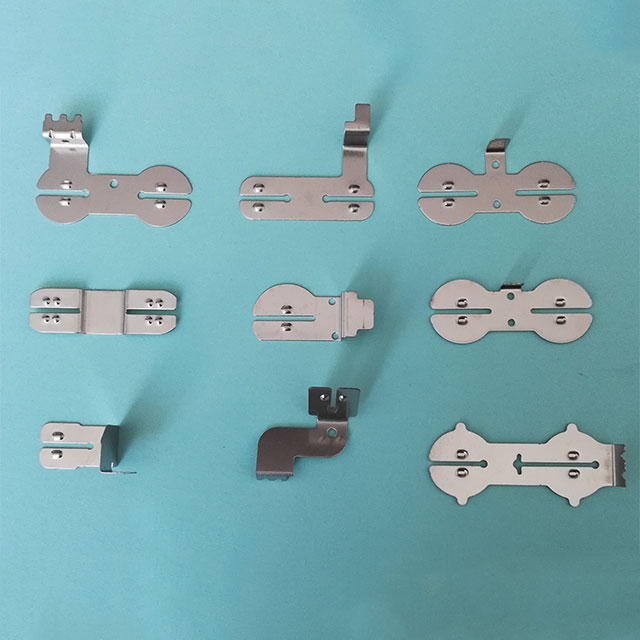

Nickel connection piece 14

Nickel connection piece 13

Nickel connection piece 12

Nickel connection piece 11

Nickel connection piece 10

Nickel connection piece 9

Nickel connection piece 8

5G communication hardware 4

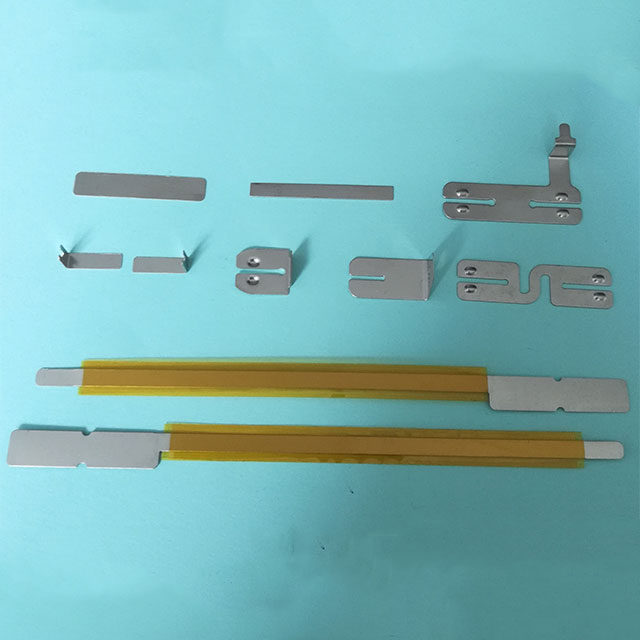

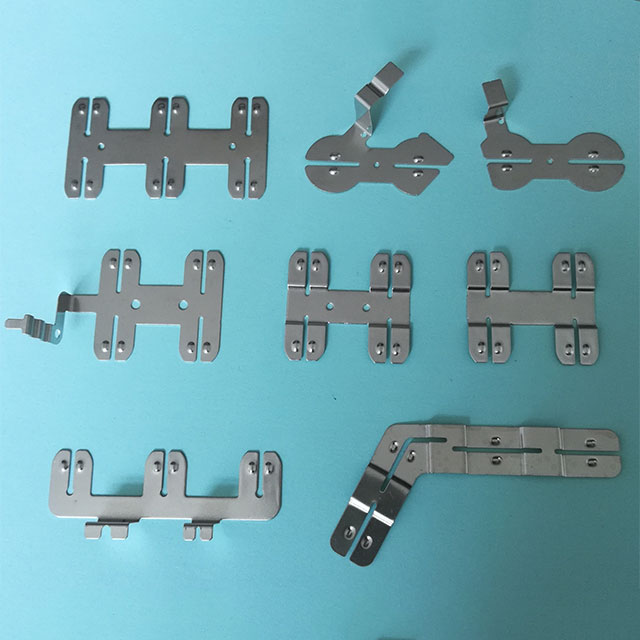

Power battery nickel sheet 7

Nickel connection piece 7

5G communication hardware 5

Power battery nickel sheet 6

Contact us

TEL+86-752-3520737-610

Phone+86-15019291973

E-mailjinggongjing@aliyun.com

AddressNankeng Village, Xinxu Town, Huiyang District, Huizhou City, Guangdong Province, China

Industry News HOME >> News >> Industry News

The surface treatment of stamping parts refers to the process of forming a covering layer on the surface of the workpiece by a certain method. The main purpose is to make the surface of the workpiece beautiful and anti-corrosive. The surface treatment methods are as follows.

Electroplating: Immerse the electroplated parts in an aqueous solution containing the metal compound to be deposited, and pass current through the plating solution to precipitate and deposit the electroplated metal on the parts. General electroplating includes zinc, copper, nickel, chromium, copper-nickel alloy and so on.

Oxidation treatment: can be divided into chemical oxidation and anodic oxidation.

Passivation treatment: pure iron and pure aluminum react in concentrated sulfuric acid or concentrated nitric acid, and the atoms on the surface react with the acid to produce a dense oxide film to prevent the internal substances from continuing to react with the concentrated acid to achieve a protective effect.

Electrophoresis: Paint is coated on the surface of the material under the action of external electric current. It is characterized by rich colors, but poor adhesion, and it is difficult to control the color uniformly.

Mechanical plating: The particles of the coated metal are used to impact the surface of the product, and the coating is cold welded to the surface of the precision stamping part.

Previous page:Advantages of metal shrapnel

Next page:Connector male and female...

24 processes behind the grinding, is a quality and rest assured.

Perform

Good craft

High quality

Experience

Faster/more efficient/quality/on-time delivery

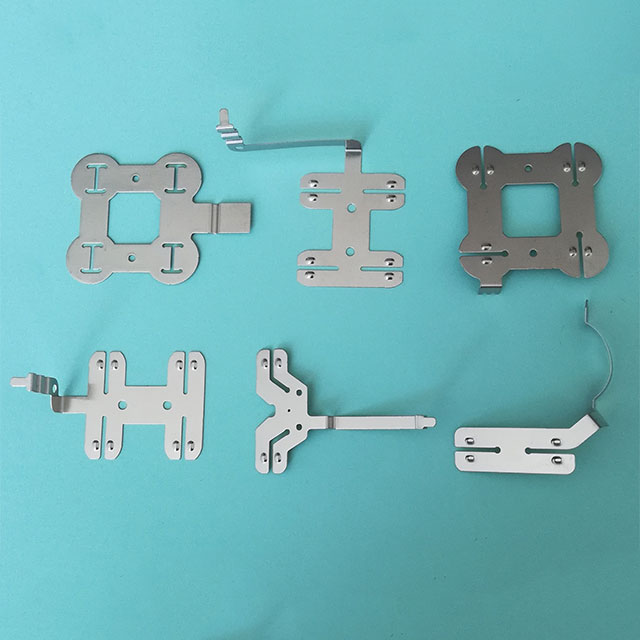

With more than 100 people mold production team, professional production team, Well-designed, precision manufacturing, fine service, excellence, Years of customized experience, first-class product technology, quality assurance, efficient and efficient production.

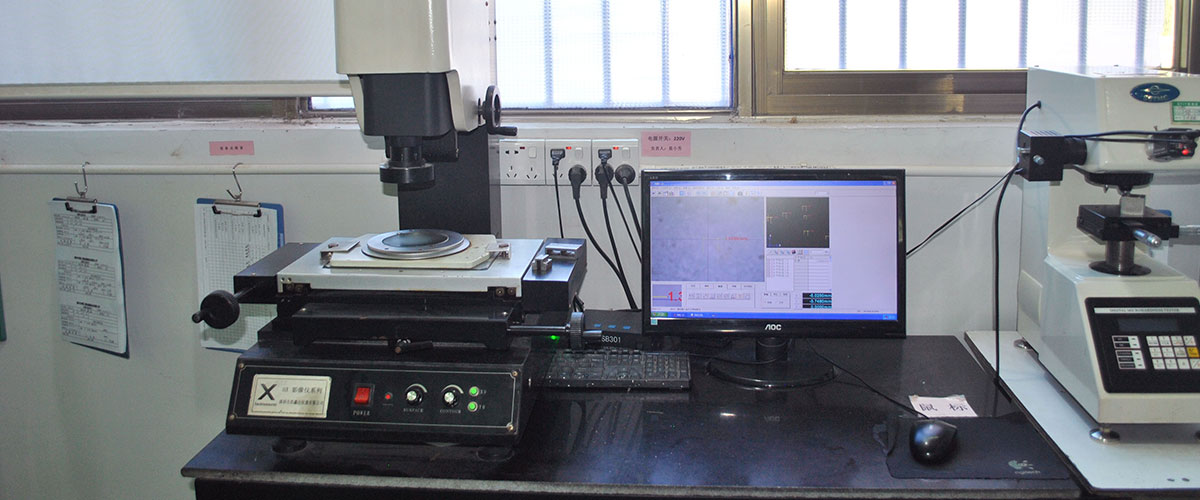

Raw materials are imported from Japan, Germany and Sweden, with stable performance and a service life of more than 5 years; Have professional heat treatment supporting services, to provide you with accurate and true heat treatment reports, strict quality inspection system and testing equipment, high precision, tolerance of up to -002um, the first in the industry.

Material sampling rationalization, save raw material costs, open the number of holes, stamping production efficiency is high, stamping processing costs savings, mold design costs are free, stamping life up to 300 million times, mold stall cost savings.

| Precise metal High cost performance service |

Eighteen years of ingenuity together, casting metal stamping products