6

Hardware

Perform

12

System

Good craft

7

Selection

High quality

18

Industry

Experience

Precision metal stamping manufacturing 18 years

+86-752-3520737

+86-15019291973

Recommended

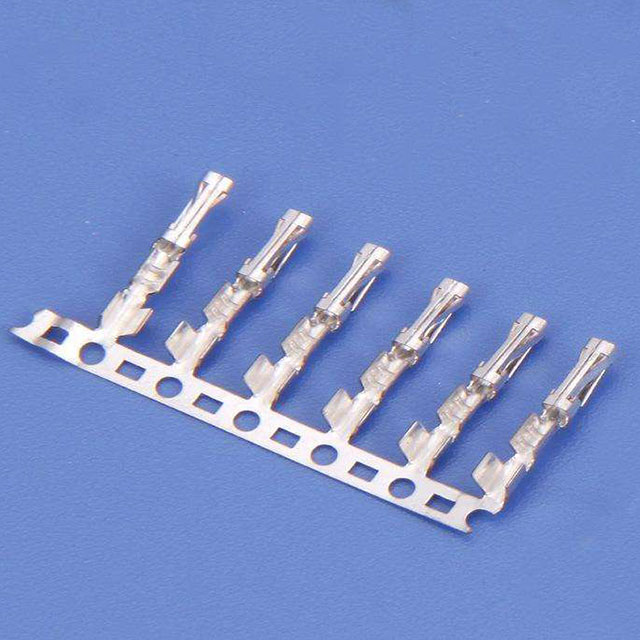

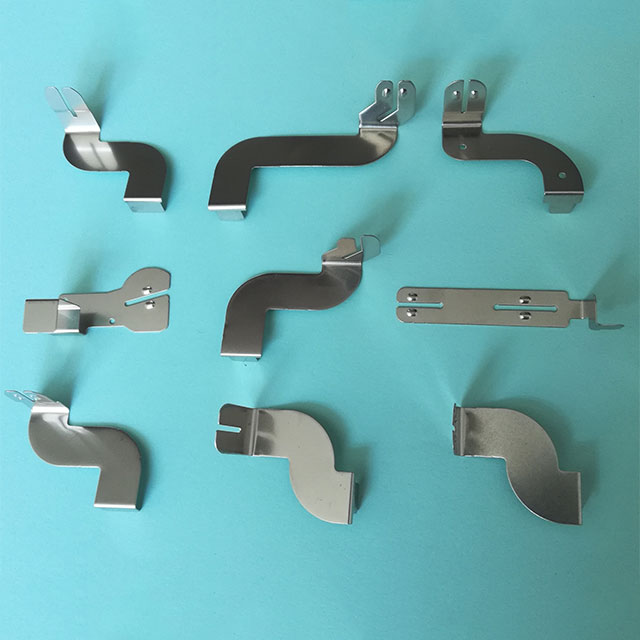

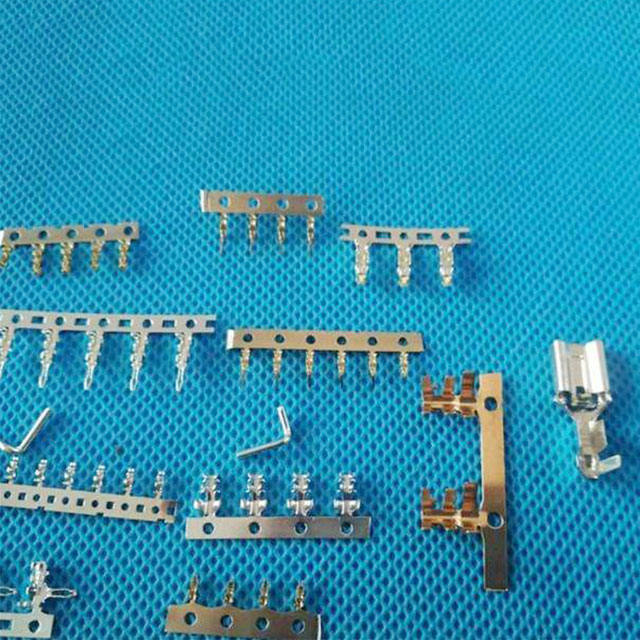

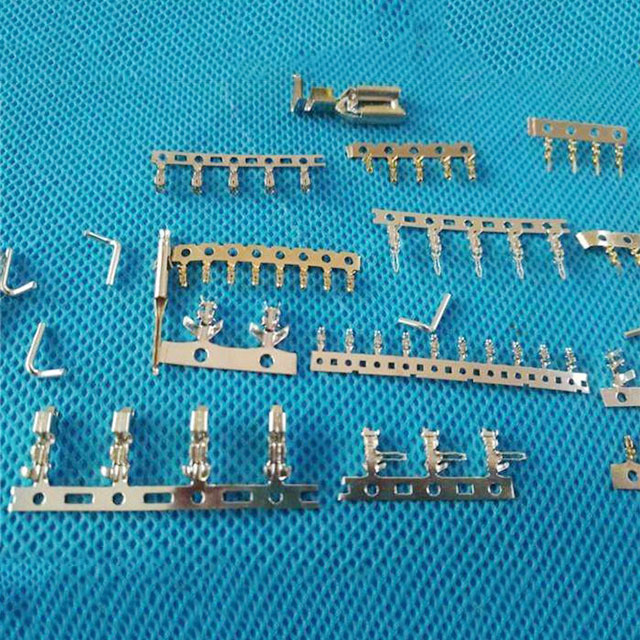

5G communication hardware 1

5G communication hardware 2

5G communication hardware 3

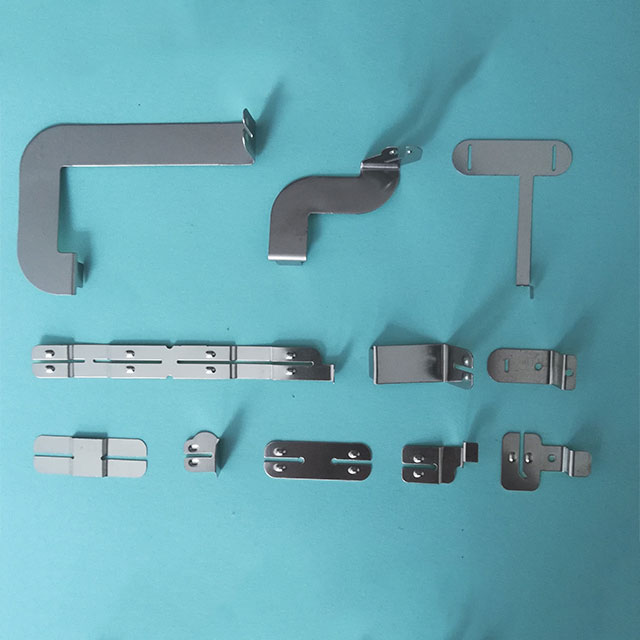

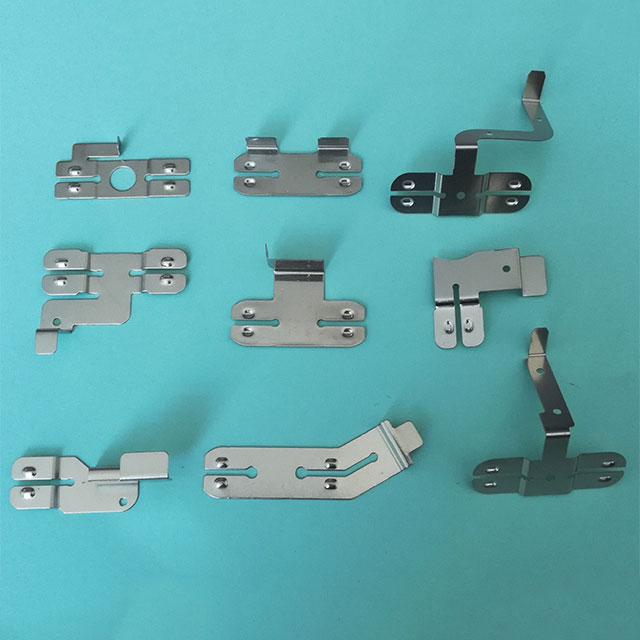

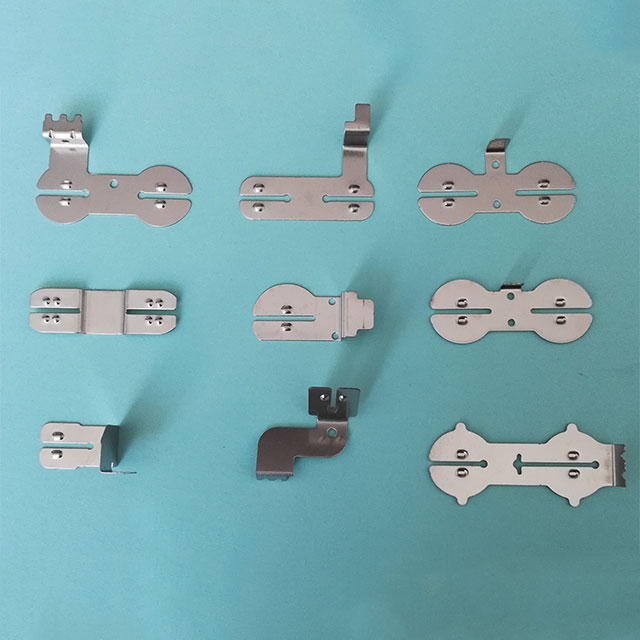

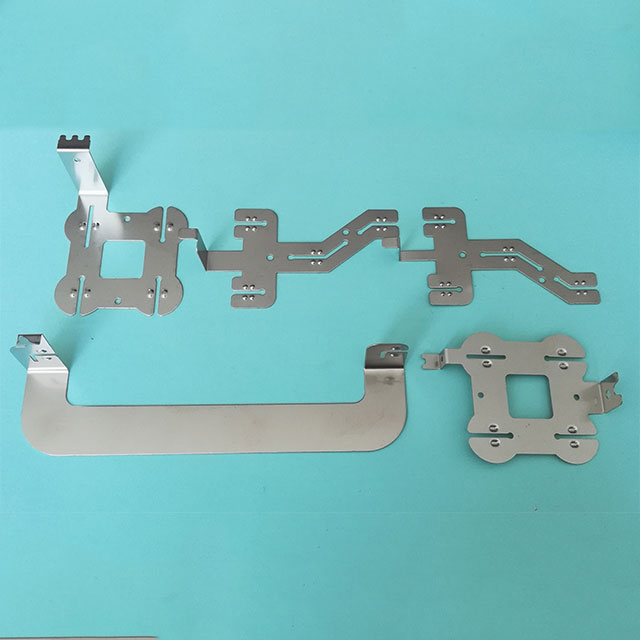

Nickel connection piece 14

Nickel connection piece 13

Nickel connection piece 12

Nickel connection piece 11

Nickel connection piece 10

Nickel connection piece 9

Nickel connection piece 8

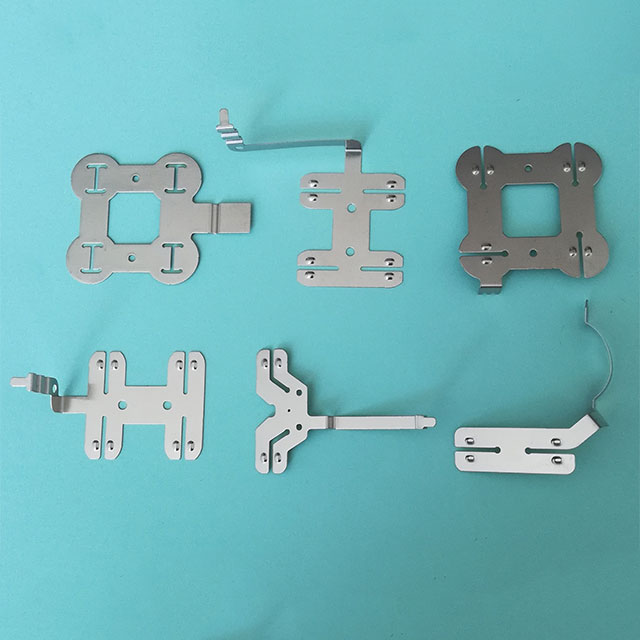

5G communication hardware 4

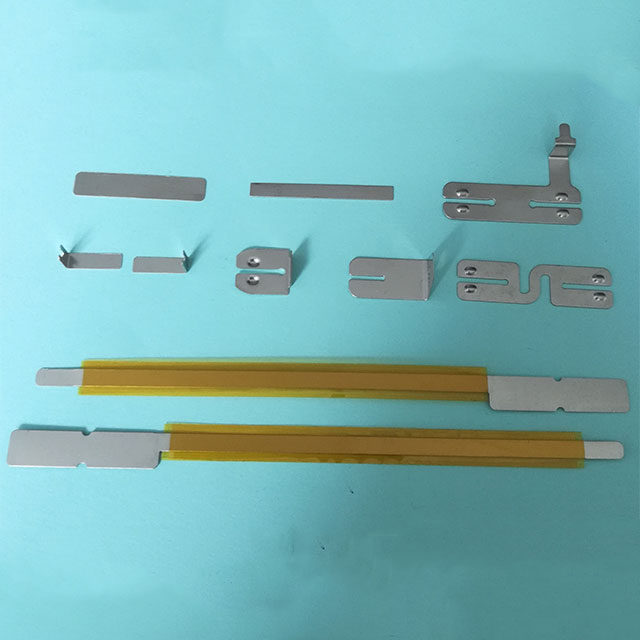

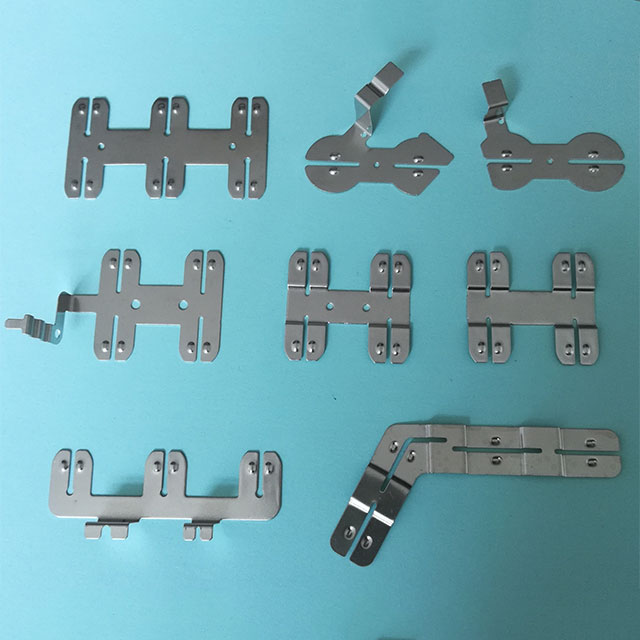

Power battery nickel sheet 7

Nickel connection piece 7

5G communication hardware 5

Power battery nickel sheet 6

Contact us

TEL+86-752-3520737-610

Phone+86-15019291973

E-mailjinggongjing@aliyun.com

AddressNankeng Village, Xinxu Town, Huiyang District, Huizhou City, Guangdong Province, China

Technical Article HOME >> News >> Technical Article

Stamping parts are needed in many fields, such as integral stamping parts in the automotive industry, automotive parts stamping parts, electrical device stamping parts, daily necessities stamping parts, household appliances stamping parts, aviation special stamping parts, etc. Therefore, the quality of stamping parts is directly related to the quality of related application products. How to improve the production efficiency of stamping parts can start from the following aspects.

The mold process card and mold pressure parameters are archived and organized, and the corresponding identification plate is made on the mold or placed in the file next to the press. You can quickly check the parameters and adjust the mold height.

In the mold production process, the intensity of self-inspection, mutual inspection, and special inspection shall be increased to prevent quality defects. Through the training of quality skills of operators, the awareness of production quality and product quality will be improved.

Improve mold maintenance efficiency, through each batch of production, mold maintenance and maintenance, improve mold service life, and improve production efficiency.

For mold failures, timely repair, tool block chipping repair welding, and mold production plate deformation are carried out on the machine tool.

Previous page:What are the advantages of...

How does the stamping factory maintain high-speed punches daily?

2020-08-15

What is the female charging port of the battery pack?

2020-08-15

Hardware shrapnel cleaning and precautions?

2020-08-15

What are the advantages of stamping?

2020-08-15

How to improve the production efficiency of stamping parts?

2020-08-15

24 processes behind the grinding, is a quality and rest assured.

Perform

Good craft

High quality

Experience

Faster/more efficient/quality/on-time delivery

With more than 100 people mold production team, professional production team, Well-designed, precision manufacturing, fine service, excellence, Years of customized experience, first-class product technology, quality assurance, efficient and efficient production.

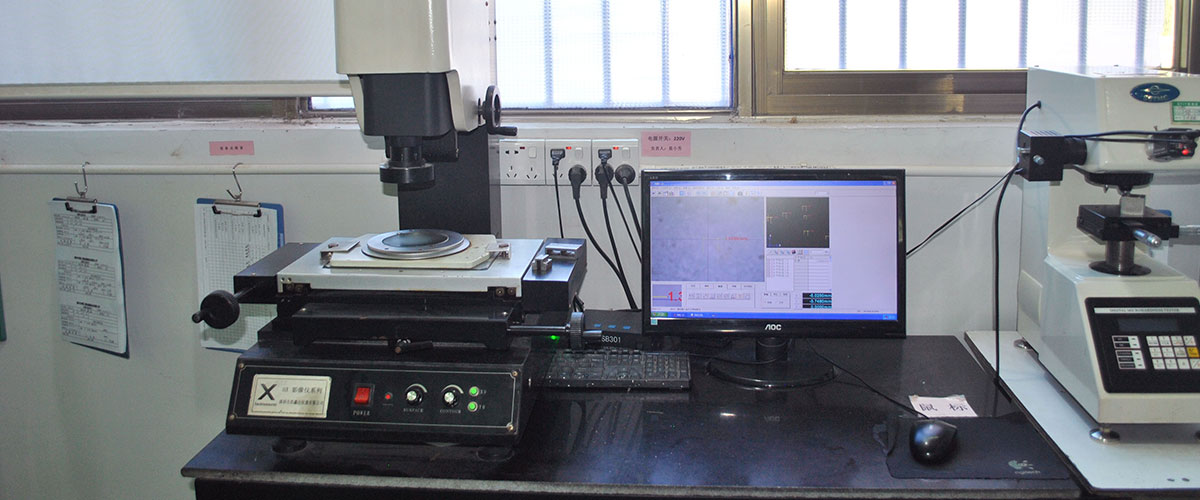

Raw materials are imported from Japan, Germany and Sweden, with stable performance and a service life of more than 5 years; Have professional heat treatment supporting services, to provide you with accurate and true heat treatment reports, strict quality inspection system and testing equipment, high precision, tolerance of up to -002um, the first in the industry.

Material sampling rationalization, save raw material costs, open the number of holes, stamping production efficiency is high, stamping processing costs savings, mold design costs are free, stamping life up to 300 million times, mold stall cost savings.

| Precise metal High cost performance service |

Eighteen years of ingenuity together, casting metal stamping products