6

Hardware

Perform

12

System

Good craft

7

Selection

High quality

18

Industry

Experience

Precision metal stamping manufacturing 18 years

+86-752-3520737

+86-15019291973

Recommended

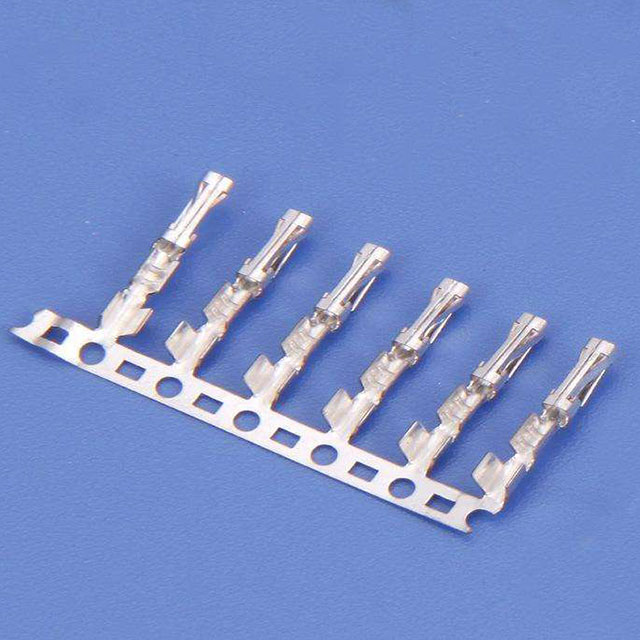

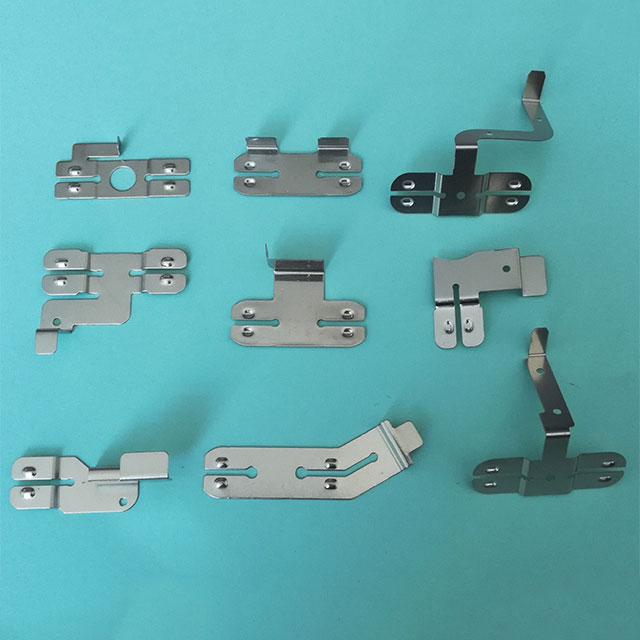

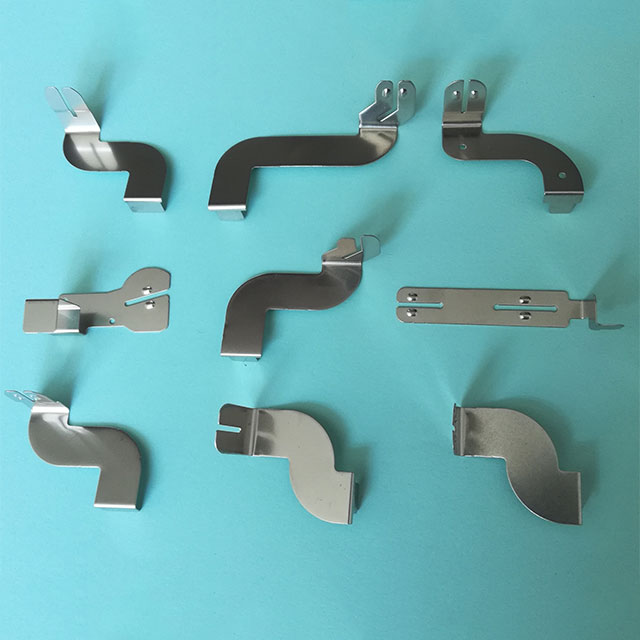

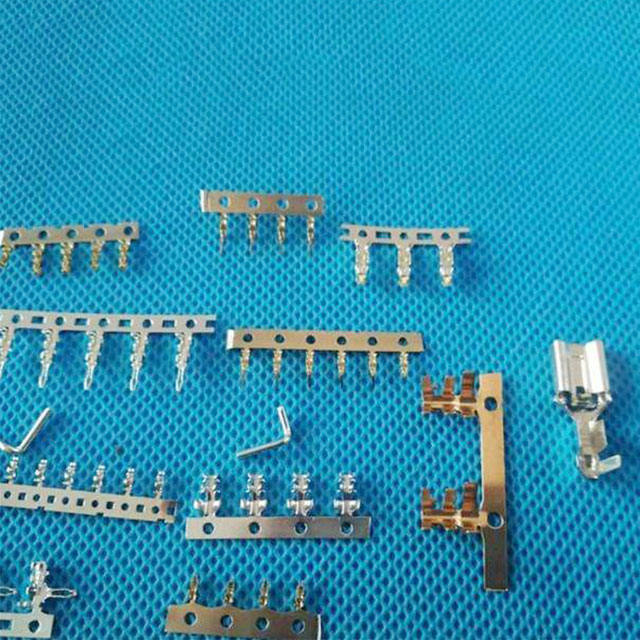

5G communication hardware 1

5G communication hardware 2

5G communication hardware 3

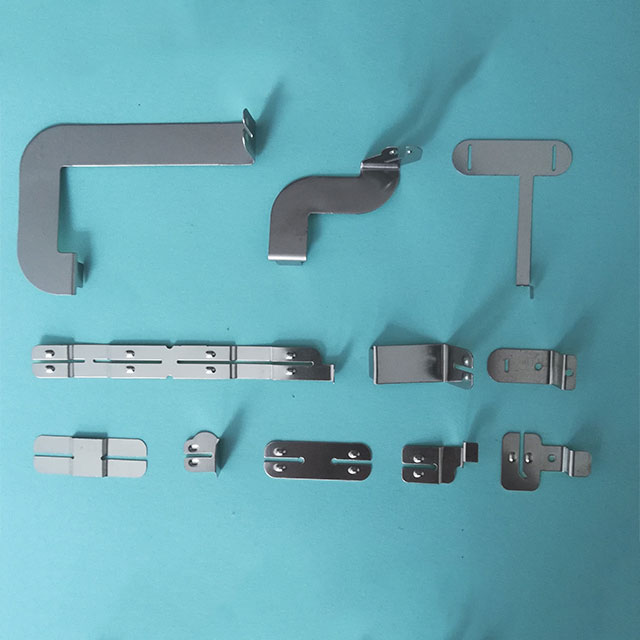

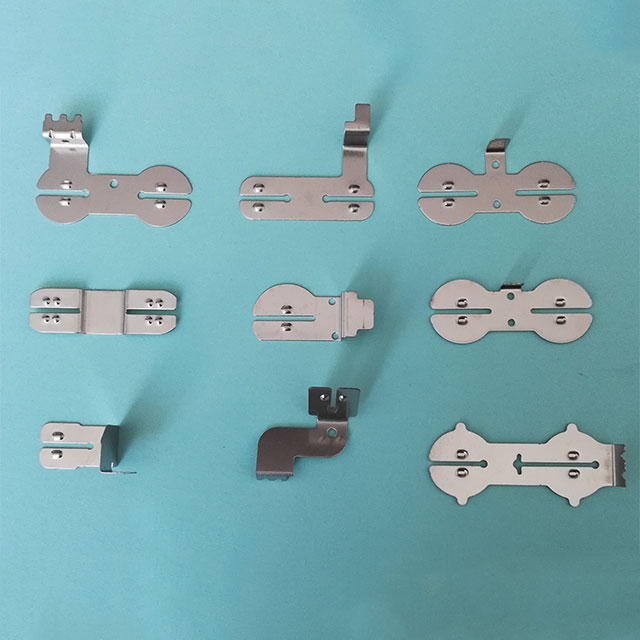

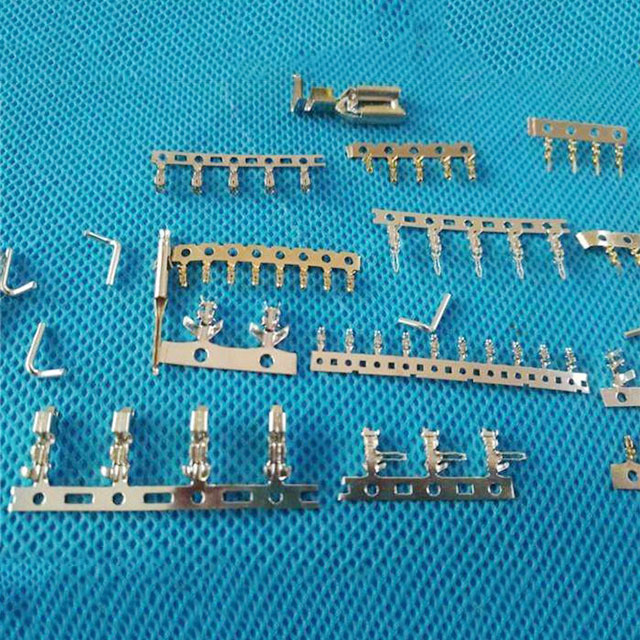

Nickel connection piece 14

Nickel connection piece 13

Nickel connection piece 12

Nickel connection piece 11

Nickel connection piece 10

Nickel connection piece 9

Nickel connection piece 8

5G communication hardware 4

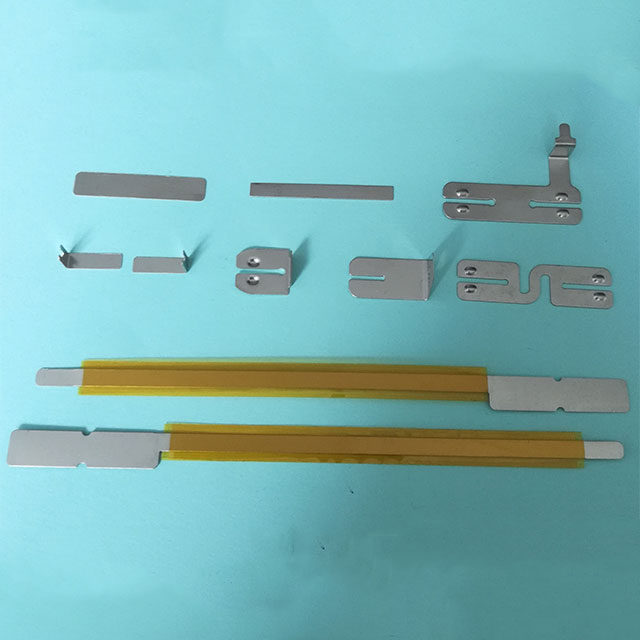

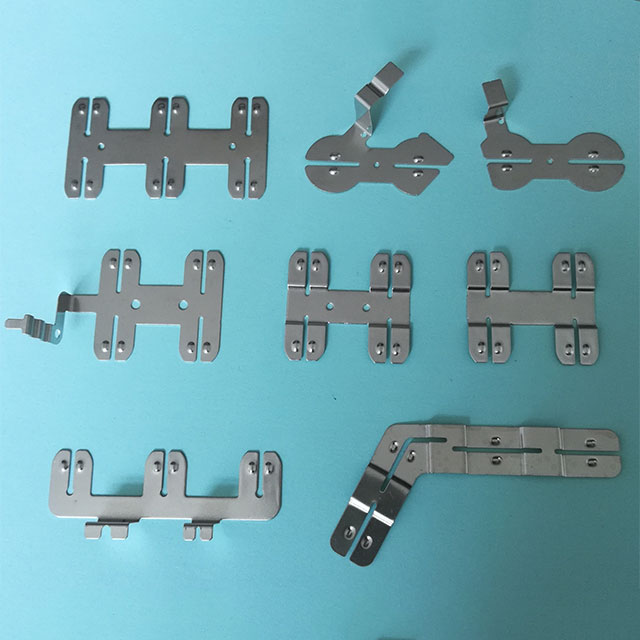

Power battery nickel sheet 7

Nickel connection piece 7

5G communication hardware 5

Power battery nickel sheet 6

Contact us

TEL+86-752-3520737-610

Phone+86-15019291973

E-mailjinggongjing@aliyun.com

AddressNankeng Village, Xinxu Town, Huiyang District, Huizhou City, Guangdong Province, China

Technical Article HOME >> News >> Technical Article

Compared with other methods of mechanical processing and plastic processing, stamping processing has many unique advantages in both technical and economic aspects.

1. The stamping process has high production efficiency, convenient operation, and easy realization of mechanization and automation. This is because stamping relies on punching dies and stamping equipment to complete processing. The number of strokes of ordinary presses can reach dozens of times per minute, and the high-speed pressure can reach hundreds or even thousands of times per minute. May get a punch.

2. When stamping, because the mold guarantees the size and shape accuracy of the stamping parts, and generally does not damage the surface quality of the stamping parts, and the life of the mold is generally longer, the quality of the stamping is stable, the interchangeability is good, and it has the "identical" feature.

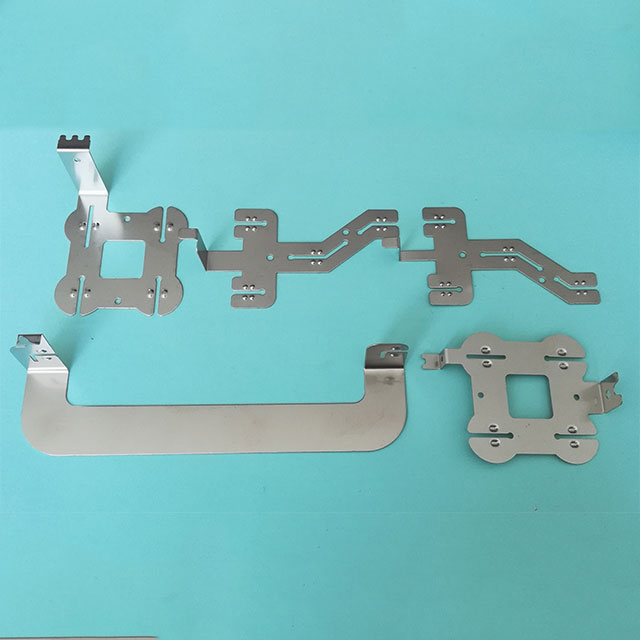

3. Stamping can process parts with a large size range and more complex shapes, such as stopwatches as small as clocks, as large as automobile longitudinal beams, covering parts, etc., plus the cold deformation and hardening effect of the material during stamping, and the strength and stiffness of the stamping Both are higher.

4. Stamping generally does not generate chips and scraps, consumes less material, and does not require other heating equipment, so it is a material-saving and energy-saving processing method, and the cost of stamping parts is lower.

5. Low investment cost. The price of ordinary punches only costs tens of thousands of yuan, and the comparative cost of high-speed precision punches and machining centers is relatively low.

In our daily life, we can see stamped products everywhere, such as stamping parts on automobiles, displays, medical equipment and daily-used metal stamping parts.

Previous page:Hardware shrapnel cleaning and...

Next page:How to improve the production ...

How does the stamping factory maintain high-speed punches daily?

2020-08-15

What is the female charging port of the battery pack?

2020-08-15

Hardware shrapnel cleaning and precautions?

2020-08-15

What are the advantages of stamping?

2020-08-15

How to improve the production efficiency of stamping parts?

2020-08-15

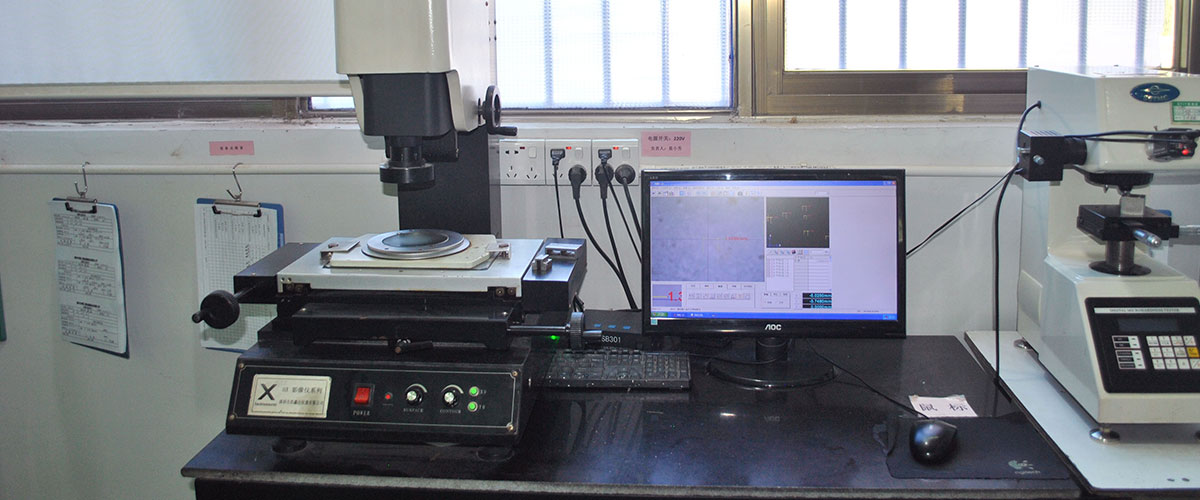

24 processes behind the grinding, is a quality and rest assured.

Perform

Good craft

High quality

Experience

Faster/more efficient/quality/on-time delivery

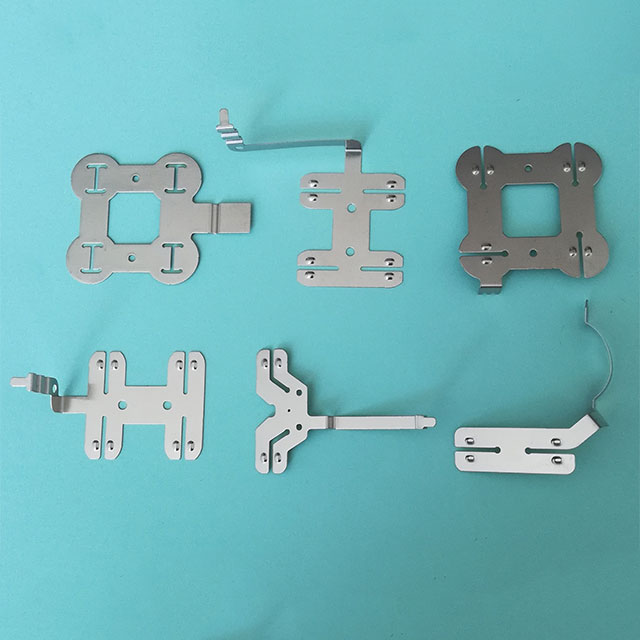

With more than 100 people mold production team, professional production team, Well-designed, precision manufacturing, fine service, excellence, Years of customized experience, first-class product technology, quality assurance, efficient and efficient production.

Raw materials are imported from Japan, Germany and Sweden, with stable performance and a service life of more than 5 years; Have professional heat treatment supporting services, to provide you with accurate and true heat treatment reports, strict quality inspection system and testing equipment, high precision, tolerance of up to -002um, the first in the industry.

Material sampling rationalization, save raw material costs, open the number of holes, stamping production efficiency is high, stamping processing costs savings, mold design costs are free, stamping life up to 300 million times, mold stall cost savings.

| Precise metal High cost performance service |

Eighteen years of ingenuity together, casting metal stamping products