6

Hardware

Perform

12

System

Good craft

7

Selection

High quality

18

Industry

Experience

Precision metal stamping manufacturing 18 years

+86-752-3520737

+86-15019291973

Recommended

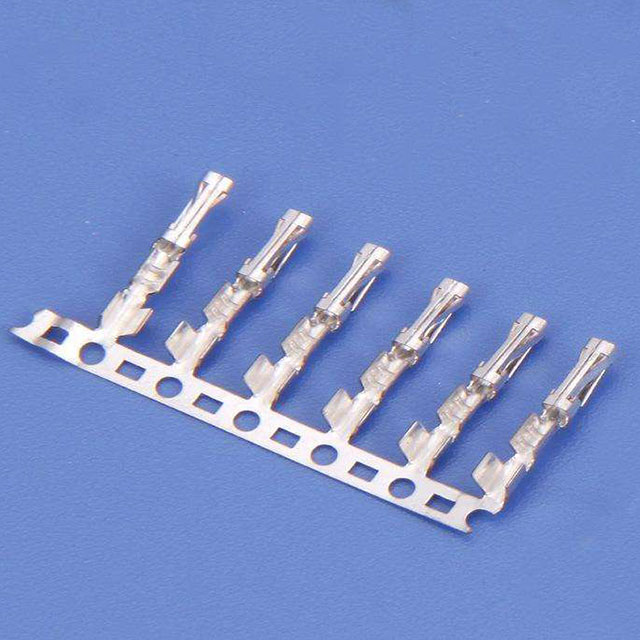

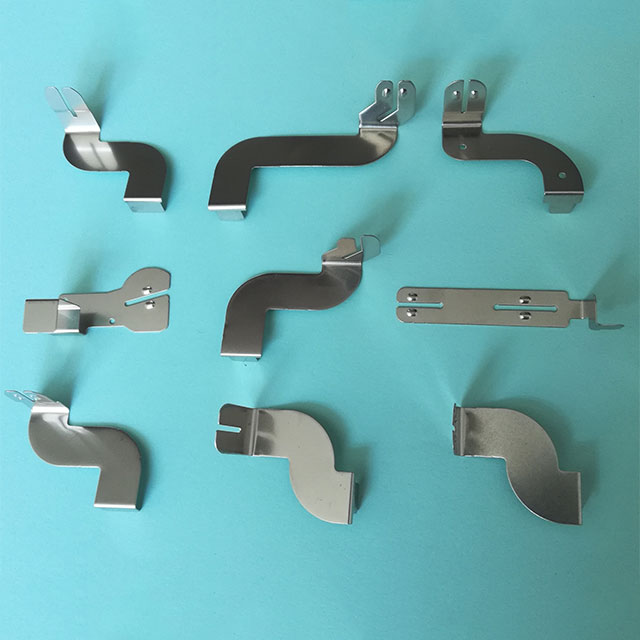

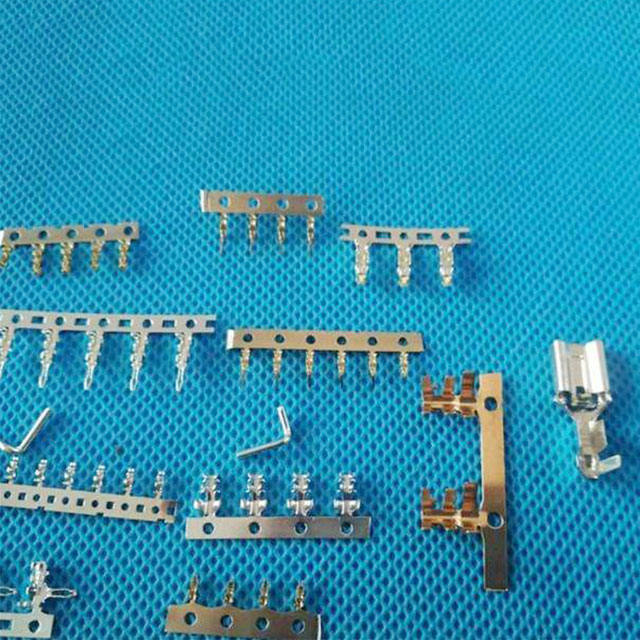

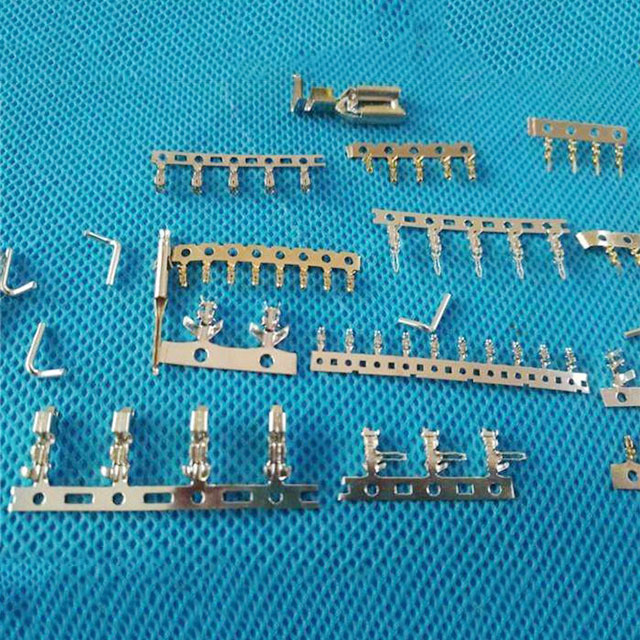

5G communication hardware 1

5G communication hardware 2

5G communication hardware 3

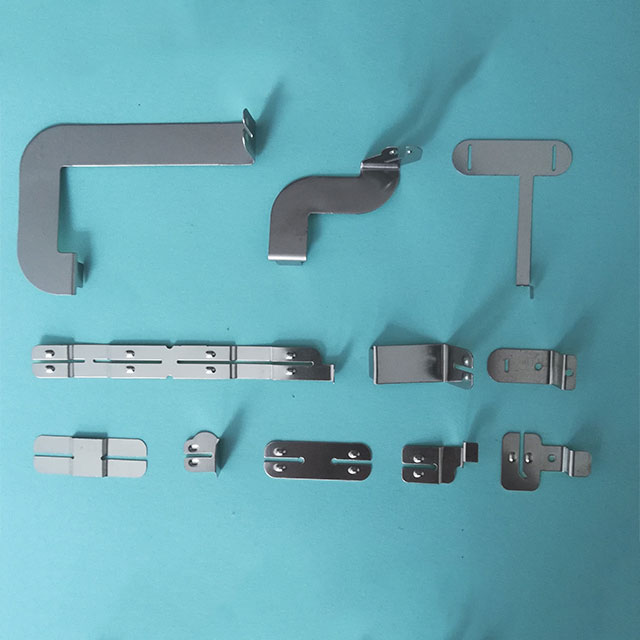

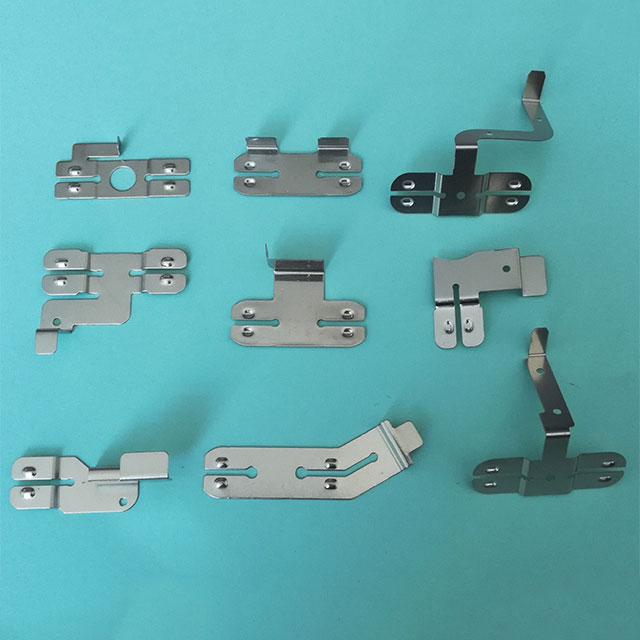

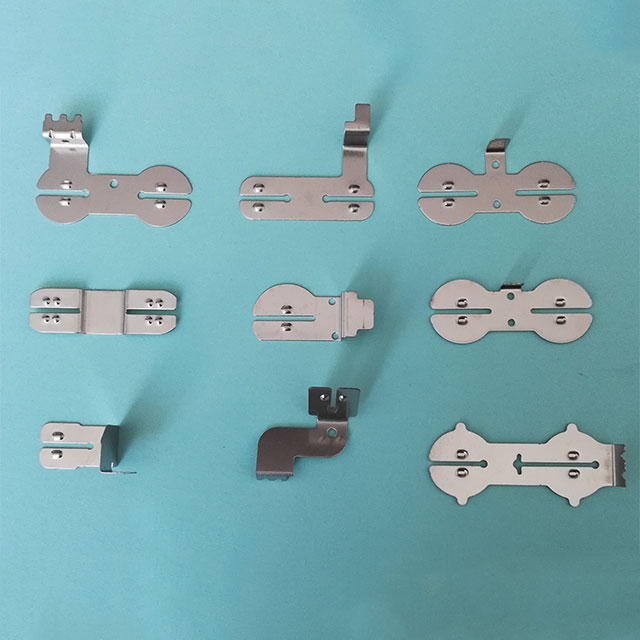

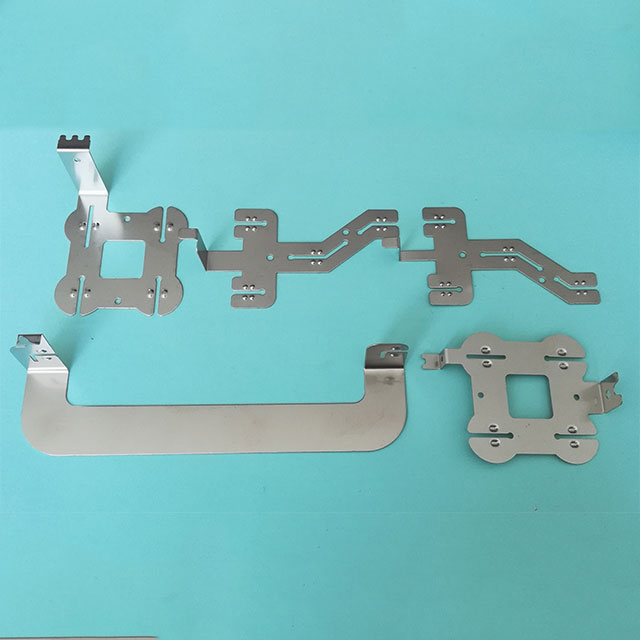

Nickel connection piece 14

Nickel connection piece 13

Nickel connection piece 12

Nickel connection piece 11

Nickel connection piece 10

Nickel connection piece 9

Nickel connection piece 8

5G communication hardware 4

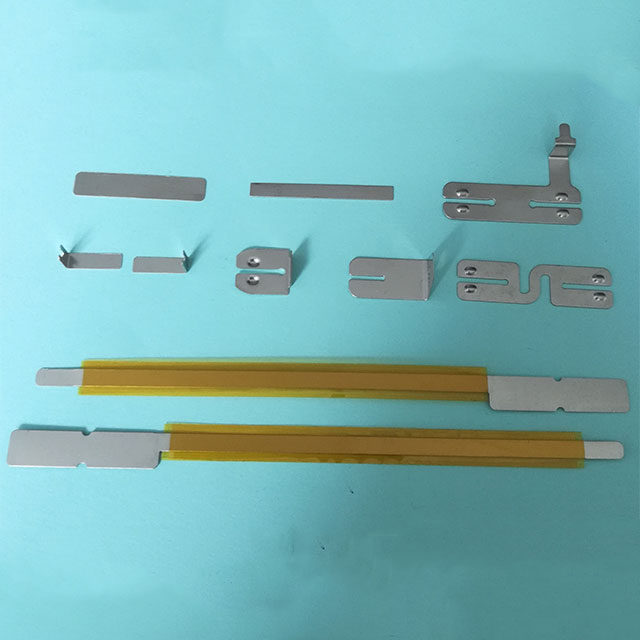

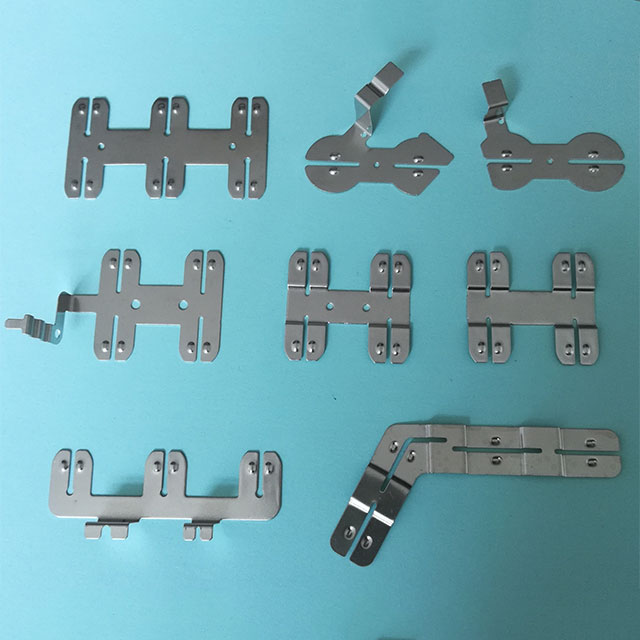

Power battery nickel sheet 7

Nickel connection piece 7

5G communication hardware 5

Power battery nickel sheet 6

Contact us

TEL+86-752-3520737-610

Phone+86-15019291973

E-mailjinggongjing@aliyun.com

AddressNankeng Village, Xinxu Town, Huiyang District, Huizhou City, Guangdong Province, China

Technical Article HOME >> News >> Technical Article

The metal shrapnel is a metal stamping part. With the help of the conductivity of the metal shrapnel, it plays a high-quality switch between the operator and the product.

Regular cleaning of metal shrapnel can prolong the service life of the metal shrapnel and reduce production. How to clean the metal shrapnel? There are the following methods for cleaning metal shrapnel:

1. The fat, oil, and lubricating oil pollution of the hardware shrapnel should be wiped dry with a soft cloth or paper and then washed with a neutral detergent or ammonia solution or special detergent; fingerprints, with alcohol or organic solvents (ether, benzene), Wipe dry with a soft cloth and then wash with water; bleach and kind of acid attached immediately rinse with water, soak in ammonia or neutral carbonated soda aqueous solution, and then wash with neutral detergent or warm water.

2. The welding of the hardware shrapnel changes color when heated, wash it with 10% nitric acid or hydrofluoric acid solution, and then neutralize it with ammonia water, carbonated soda light solution, and then wash the stainless steel spring with water—special use for washing medicine; organic carbide adheres to soak in the hot A neutral detergent or ammonia solution is then washed with a weakly abrasive detergent.

3. Use warm water and weak detergent to scrub labels and films; use soap, weak detergent or warm water to clean dust and dirt easily; use alcohol or organic solution for binder components; surface contamination of metal shrapnel Use nitric acid (10%) or abrasive detergent to wash the rust caused by the use of special detergents. Use detergent or oil to cause excessive rainbow patterns. Use warm water detergent when washing.

The precautions for cleaning hardware shrapnel are as follows:

1. When washing, please be careful not to scratch the surface. Avoid using bleaching ingredients and detergents containing abrasives, steel balls (brush roller balls), grinding tools, etc., in order to remove the detergent, after washing, rinse the surface with clean water .

2. When cleaning stainless steel products, try to ensure that the damage on the surface of the stainless steel is minimized, so that the stainless steel products look more comfortable and more comfortable to use.

3. In daily life, we often see that although stainless steel does not rust, stains often appear on the surface. Stainless steel springs are a bit more difficult than ordinary stainless steel, so some small tricks should be used to deal with them.

Previous page:What is the female charging...

Next page:What are the advantages of...

How does the stamping factory maintain high-speed punches daily?

2020-08-15

What is the female charging port of the battery pack?

2020-08-15

Hardware shrapnel cleaning and precautions?

2020-08-15

What are the advantages of stamping?

2020-08-15

How to improve the production efficiency of stamping parts?

2020-08-15

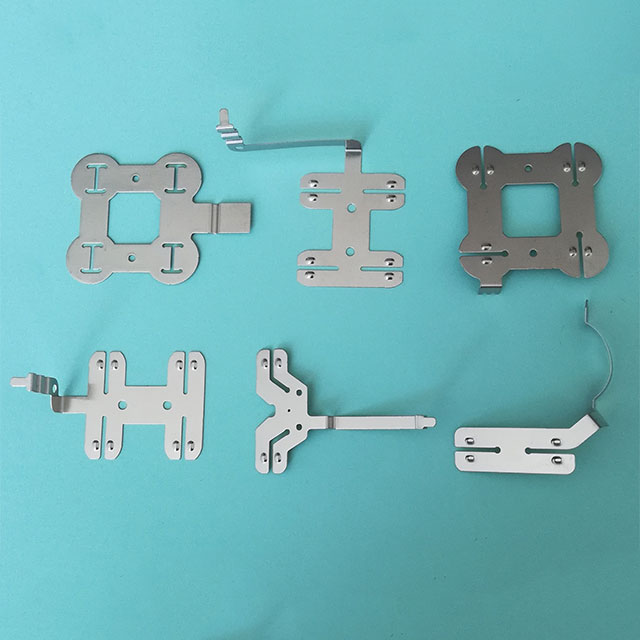

24 processes behind the grinding, is a quality and rest assured.

Perform

Good craft

High quality

Experience

Faster/more efficient/quality/on-time delivery

With more than 100 people mold production team, professional production team, Well-designed, precision manufacturing, fine service, excellence, Years of customized experience, first-class product technology, quality assurance, efficient and efficient production.

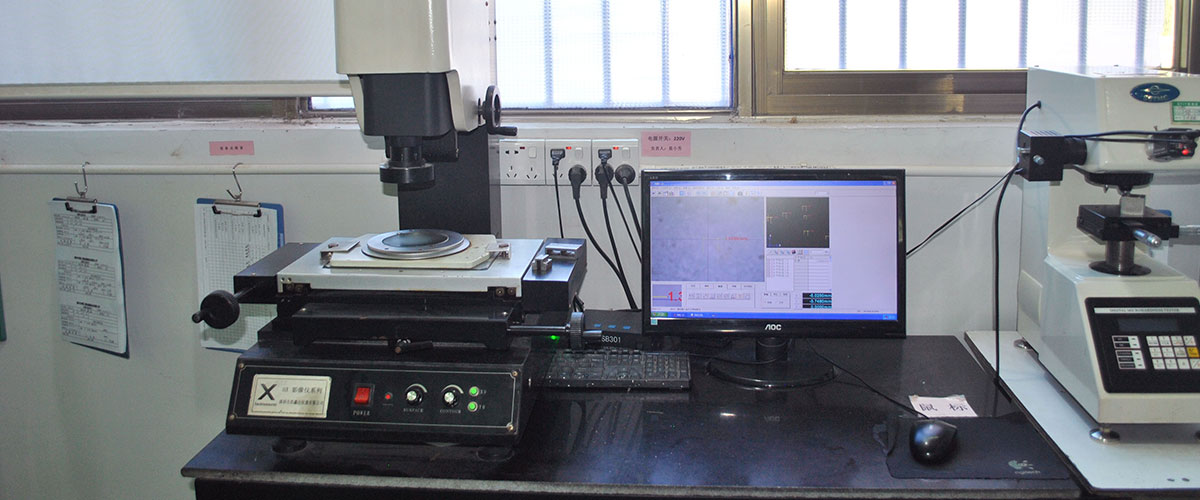

Raw materials are imported from Japan, Germany and Sweden, with stable performance and a service life of more than 5 years; Have professional heat treatment supporting services, to provide you with accurate and true heat treatment reports, strict quality inspection system and testing equipment, high precision, tolerance of up to -002um, the first in the industry.

Material sampling rationalization, save raw material costs, open the number of holes, stamping production efficiency is high, stamping processing costs savings, mold design costs are free, stamping life up to 300 million times, mold stall cost savings.

| Precise metal High cost performance service |

Eighteen years of ingenuity together, casting metal stamping products